With the growing adoption of electric vehicles, continued interest in renewable energy, and the rising demand for reliable backup power, the global energy storage market is growing faster than ever before. However, despite this growth, industries continue to face challenges sourcing batteries and energy storage solutions internationally. Long lead times, shipping delays, and geopolitical instability all put pressure on companies that rely on overseas suppliers. For OEMs and industries seeking consistency and security, choosing a U.S.-based manufacturer is a strategic decision. By working with a domestic partner like Lithium Battery Company (LBC), organizations gain access to advanced automation, rigorous quality control, and reliable customization, all while strengthening the economic and strategic foundation of American manufacturing.

Supply Chain Reliability and Security

Energy storage projects often depend on precise timelines, and delays can cause significant setbacks. Overseas suppliers are vulnerable to global disruptions, including trade disputes, tariffs, pandemics, and logistical bottlenecks can all stretch delivery windows from weeks into months. Recent U.S. legislation, such as the Inflation Reduction Act and CHIPS Act, incentivizes domestic battery production, while tariffs on certain imported cells and materials increase the cost of relying on foreign vendors

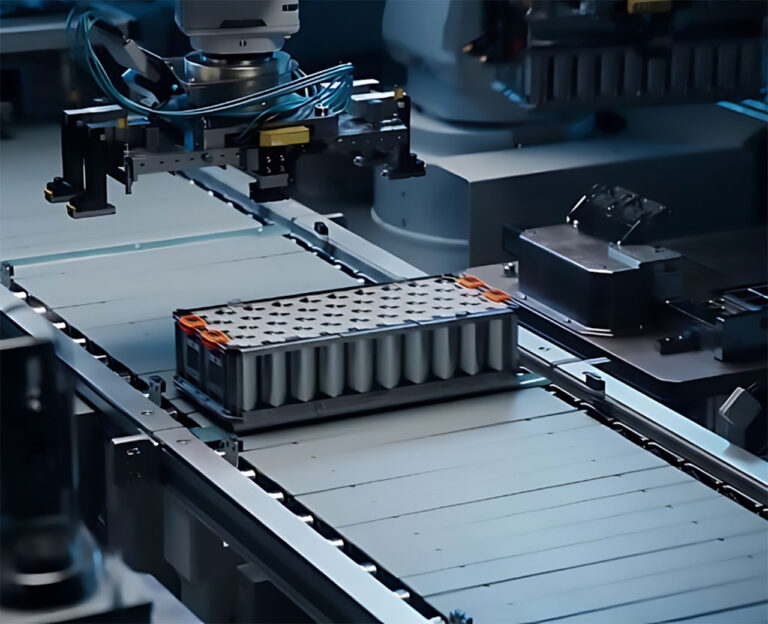

By working with a U.S.-based partner, OEMs benefit from shorter, more predictable lead times. Domestic sourcing eliminates costly ocean freight and reduces the risk of shipping delays. At LBC’s 60,000-square-foot automated facility in Tampa, Florida, orders are managed end-to-end within the United States. This gives customers confidence that their battery systems will arrive on schedule.

Quality Control and Standards

Performance and safety are non-negotiable in energy storage. One of the key advantages of working with a U.S.-based manufacturer is the ability to maintain tighter oversight over the entire production process.

At LBC, automation and cleanroom assembly ensure that every lithium battery pack meets exacting specifications. Advanced testing protocols validate performance before products leave the facility. It also ensures every system is manufactured in compliance with U.S. regulatory standards. For industries such as defense, healthcare, and data centers, where reliability is crucial, this level of oversight provides assurance that overseas mass production cannot guarantee.

Faster Customization for OEM Needs

Every industry has unique requirements, and mass-market battery packs often fall short of meeting specialized demands. Overseas suppliers typically prioritize volume production, which leaves OEMs with limited flexibility to request modifications.

By contrast, domestic partners like LBC offer agile customization. The Tampa facility supports both cylindrical and prismatic battery pack assembly, as well as advanced chemistries including LFP, NCM, and sodium-ion. Whether the application is renewable energy storage, electric marine systems, or defense robotics, LBC designs tailored solutions that optimize performance, safety, and scalability for each client’s needs.

Economic and Strategic Advantages

Working with a U.S.-based company also delivers broader economic and strategic value. Reshoring battery sourcing can strengthen national supply chains, create jobs, and support innovation in the US. For critical industries, such as defense, aerospace, and AI/data centers, domestic sourcing also enhances national security by reducing dependence on foreign suppliers.

Lithium Battery Company’s Tampa facility is designated as a Foreign Trade Zone (FTZ). This enables streamlined global trade for international partners while keeping manufacturing anchored in the U.S. This unique advantage allows LBC to serve both domestic and international markets efficiently while reinforcing America’s leadership in advanced energy storage.

Comparison: Overseas vs. U.S.-Based Energy Storage Partners

| Factor | Overseas Supplier Risk | U.S.-Based Advantage (LBC) |

|---|---|---|

| Lead Times | Weeks to months | Shorter, predictable delivery |

| Quality Oversight | Limited visibility | Automated U.S. facility with cleanroom assembly |

| Supply Chain Security | Vulnerable to disruptions | Stable, domestic production |

| Customization | Mass-market focus, limited options | Tailored OEM solutions |

| Economic Impact | Jobs overseas | Supports U.S. innovation and jobs |

In today’s rapidly expanding energy storage landscape, the decision to work with a U.S.-based manufacturer is about reliability, security, and long-term value. By sourcing domestically, OEMs gain faster delivery, higher quality, and the flexibility to design systems that meet the specific demands of their industry. At the same time, they support local jobs, strengthen national supply chains, and contribute to the reshoring of critical technologies.

Lithium Battery Company is proud to lead this shift with its advanced automated facility in Tampa, Florida. By combining precision manufacturing, rigorous quality testing, and flexible customization, LBC delivers energy storage solutions designed to power the industries of today and tomorrow.

Partner with Lithium Battery Company!

For OEMs and industry leaders seeking a trusted partner for energy storage, Lithium Battery Company is the U.S.-based solution that provides confidence, performance, and innovation. Contact us today to explore energy storage solutions.