Reshoring Battery Manufacturing

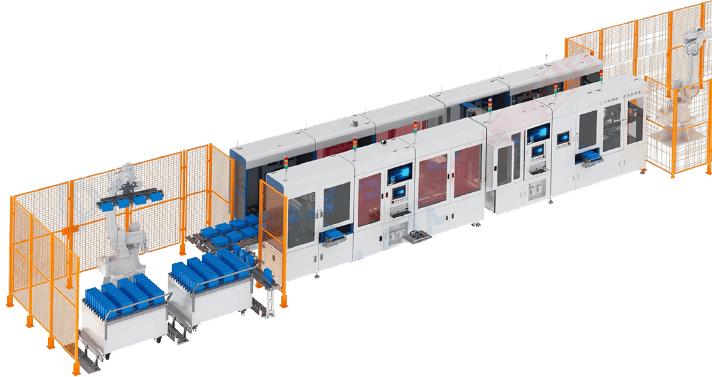

Fully Automated Battery Pack Manufacturing Solutions

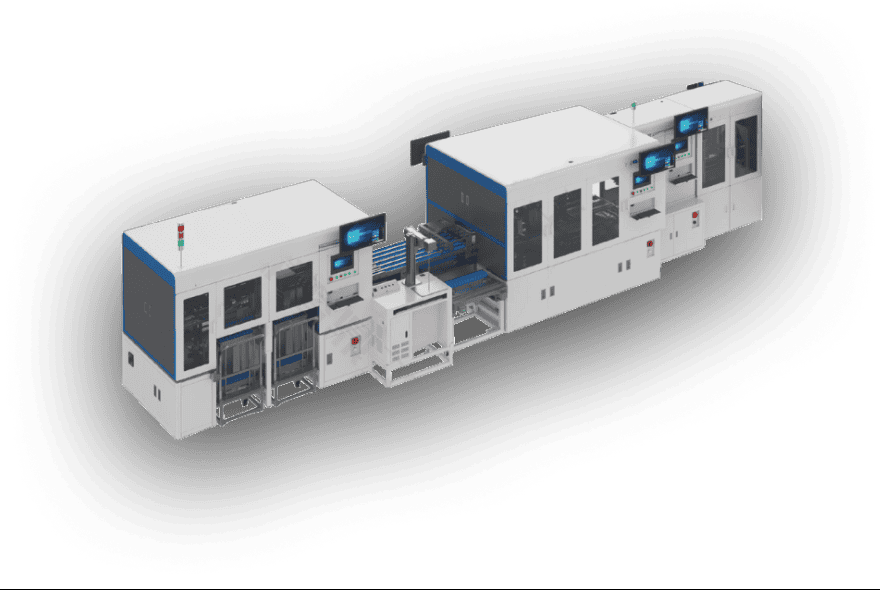

Discover the next generation of battery manufacturing at our cutting-edge facility, where advanced automated assembly lines deliver unparalleled precision and efficiency, proudly revitalizing American jobs through reshoring innovation.

Your U.S.-Based

Battery Manufacturing Partner

We help OEMs transition from overseas production to domestic, automated battery assembly. Our mission is to strengthen American manufacturing through scalable, high-output solutions tailored to your needs from prototype to production.

Automation

Built for Every

Step of Production

Our process begins with custom-configured assembly lines designed around your product. We use robotics, real-time monitoring, and in-line testing to build lithium battery packs with unmatched speed, accuracy, and traceability.

A Facility Designed

For Tomorrow’s Demands

Our Capabilities Include:

Robotic welding and real-time defect detection

Cleanroom-ready environments for sensitive builds

End-of-line safety testing and BMS integration

High-volume throughput (up to 2,000 packs/day)

Prototyping support for pilot runs and fast iteration

ISO 9001 and IATF 16949 certification (in progress)

Elite Battery Pack

Manufacturing Capabilities

Our Capabilities Include:

Robotic welding and real-time defect detection

Fully automated assembly line for prismatic batteries ranging from 50AH to 320AH.

Precision engineering for automotive and industrial applications.

Seamless integration with existing systems.

High-Capacity Cylindrical Lithium Battery Manufacturing

Fully automated line for large cylindrical batteries, including 32130, 32125, 32140, 22140, 40130, and 4680 models.

Ideal for energy storage and heavy-duty applications.

High-speed automation for increased throughput.

Compact Cylindrical Lithium Battery Manufacturing

Fully automated line for small cylindrical batteries, specifically 18650, 21700, 26650, and 32700 models.

Perfect for consumer electronics and portable devices.

Flexible production with rapid prototyping capabilities.

Why Choose Us?

faster time-to-market vs.

offshore suppliers

automated production lines

tariff mitigation strategies

built into every project

From Consultation

to Production in 90 Days

1 Contact

2 Consultation

3 Tailored Solution

4 Seamless Transition

Pre-qualified responses within 48 hours

Our proprietary ReshoreAI™ analyzes your project for:

- Tariff exposure risks

- Localized supply chain options

- Improving efficiency

Integration with Existing Factories:

In most cases, we can work with your existing factories overseas and incorporate USA components with our network of suppliers.

Ready to

Reshore Your

Battery Manufacturing?

Explore how U.S.-based automation can reduce lead times, improve quality, and streamline your path to market.