Don't compromise on quality or efficiency...

your project deserves a battery tailored to your specific needs. Our batteries are not just reliable; they are a smart investment, saving you invaluable time and resources in the long run. J

Cost-Effective Technology

Our BMS innovation is the key to reduced costs without sacrificing quality.

Tailored for Excellence

Avoid the pitfalls of inadequate batteries; opt for a solution designed for your success.

Professional Integration

From concept to completion, we’re with you every step to ensure first-time success.

Trusted by Industry Leaders: Our Partners in Innovation

Join the ranks of Original Equipment Manufacturers who trust in our technology to light up their new product development. Experience the power of precision with our lithium-ion batteries—because every detail counts when it comes to powering progress.

Shop Lithium Battery Voltage

Harness the power of efficiency and longevity with our premium range of Lithium Batteries. Each battery is expertly crafted to deliver unmatched performance and durability, ensuring that energy needs are met with precision and reliability.

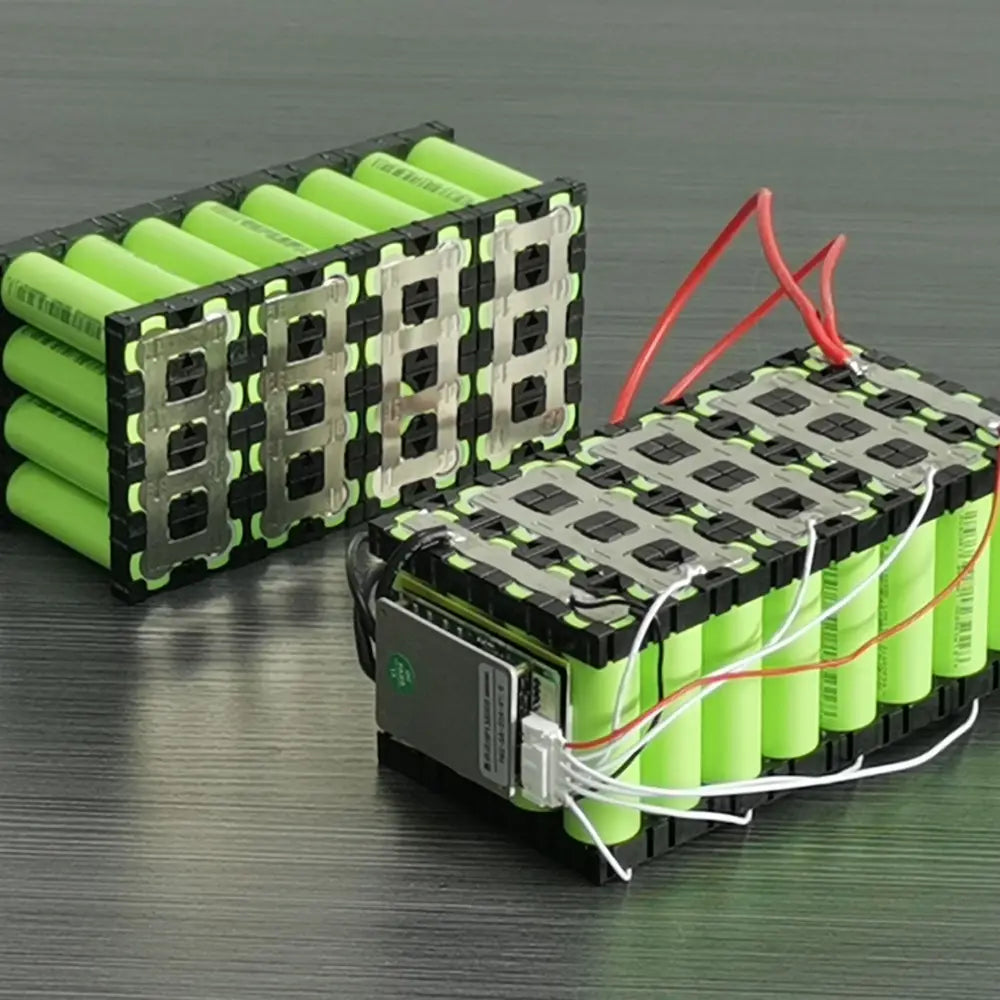

Customized Lithium Battery Solutions

In the forefront of innovation, our lithium battery solutions power essential technology, from handheld devices to heavy machinery. We specialize in creating custom batteries tailored to the diverse needs of various industries, leveraging our engineering expertise for precise, efficient performance. Our consulting services help identify the best battery configuration for your specific needs, emphasizing innovation, quality materials, and safety standards.

For businesses running electric fleets, overseeing remote operations, or requiring dependable consumer product power sources, explore how our bespoke lithium battery solutions can boost your operations. Book a consultation with our experts today and propel your projects with unmatched precision and confidence.

Tailored for Every Need

Understanding that each application has unique power requirements, our company specializes in designing custom lithium battery packs to meet the specific needs of OEMs and product developers.

Integration Expertise

Our expertise in integrating lithium battery solutions into new and existing products ensures seamless performance, reliability, and safety, enhancing the overall product value.

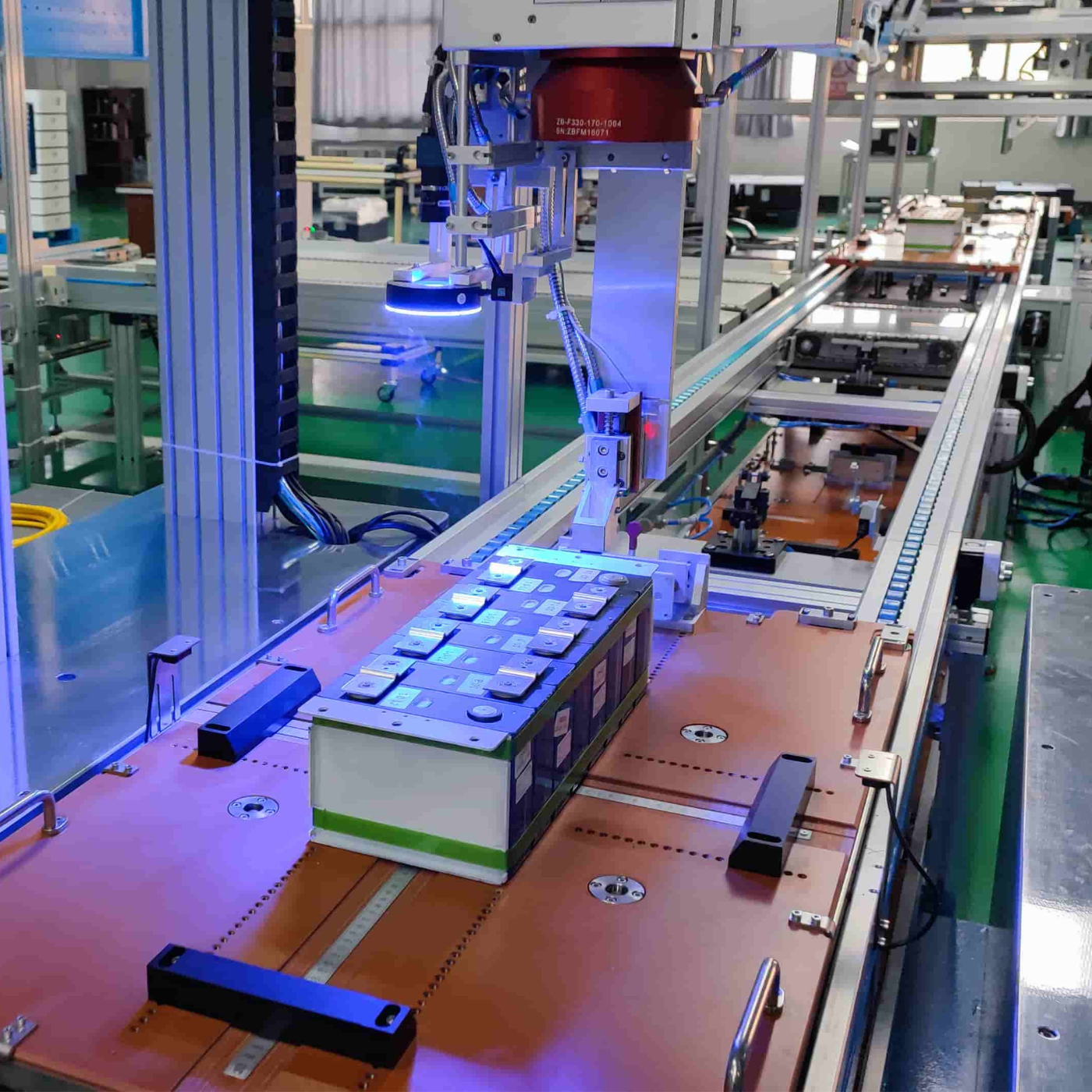

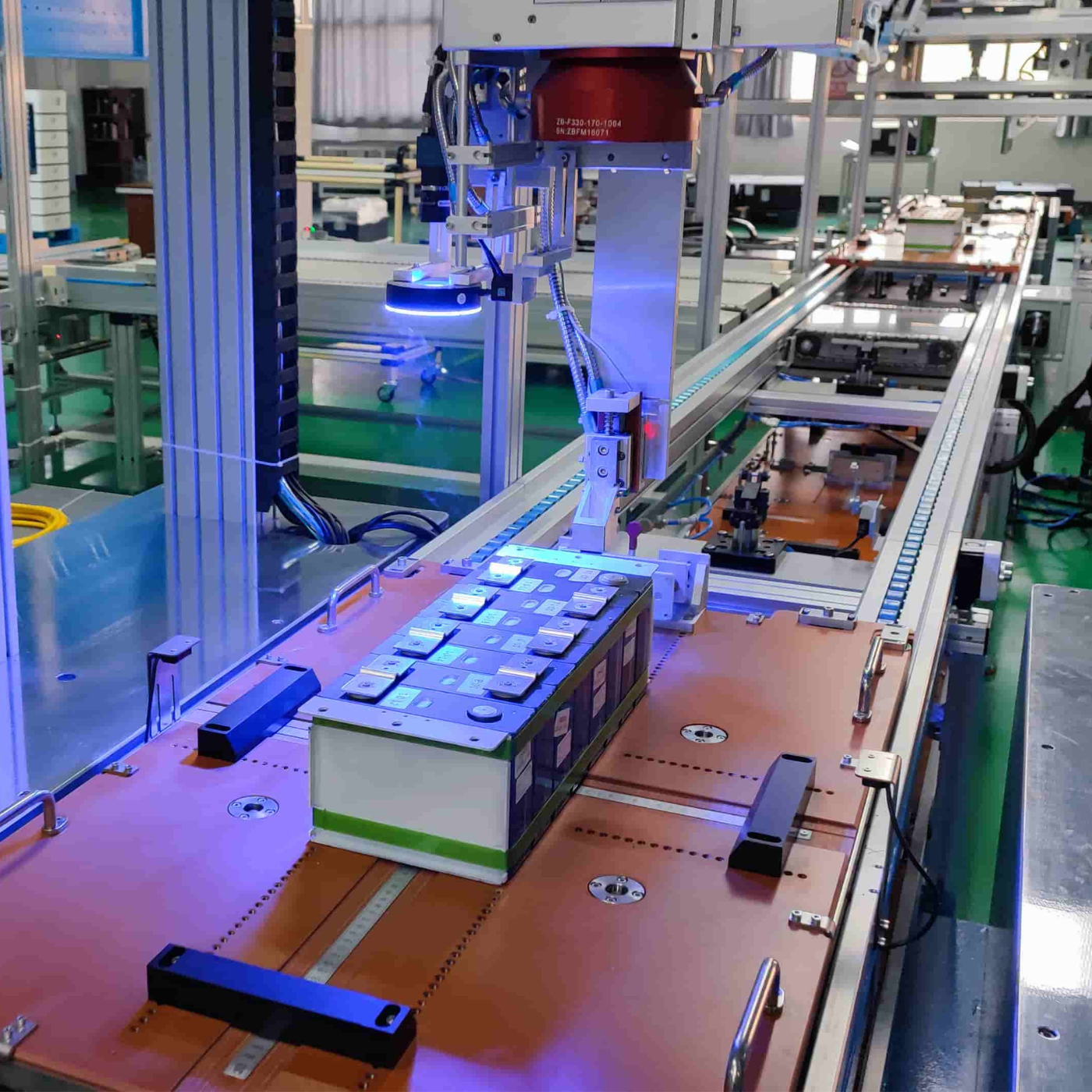

State-of-the-Art Facility

Our commitment to quality is reflected in our state-of-the-art assembly facility, where precision and innovation converge to produce top-tier lithium battery packs.

Our Innovative Lithium Battery Technology for the Top 10 Industries

Lithium Batteries For Any Application

Our lithium ion batteries are the perfect choice for powering your business. Our innovative battery technology is designed to provide reliable and efficient power for a variety of applications. Our batteries are perfect for the top 10 industries that need our battery technology, including automotive, medical, and consumer electronics.

Quality & Performance

Our lithium-ion batteries are engineered for those who demand excellence. Featuring advanced technology that powers your devices and equipment longer, our batteries are synonymous with quality and efficiency. Whether it's for industrial, personal, or recreational use, these batteries are designed to keep up with the rigorous demands of daily operations.

A Voltage for Every Need

With a versatile selection of voltage options, our collection is tailored to cater to a wide array of applications. Discover the ultimate power solution with our extensive selection of lithium batteries, including highly sought-after 24V lithium batteries, 36V lithium batteries, 12V lithium batteries, and 48V lithium batteries. Our product range is meticulously designed to accommodate a variety of needs, making us the go-to source for high voltage lithium batteries and custom lithium battery packs.

Discover the Ideal Battery

We invite you to explore our selection and find the lithium battery that suits your unique needs. With easy-to-navigate categories and detailed product specifications, our website simplifies the process of selecting the ideal energy source for any use case. Experience the difference in power and performance - shop with us today.

Optimize your energy solutions with our range of lithium batteries and ensure that your devices are powered by the best. Questions? Our knowledgeable customer service team is ready to assist you in making the right choice. ***Shop now and energize your world with the best that lithium battery technology has to offer.

CONTACT US TODAY!Original Equipment Manufactures (OEMs)

At Lithium Battery Company, we pride ourselves on our ability to work closely with OEMs to create custom lithium-ion battery solutions for any application. Our team of experienced engineers and designers can work with you to tailor the performance and specifications of your battery to meet your exact requirements. With a focus on innovation and quality, we utilize cutting-edge technology and rigorous testing procedures to ensure that our batteries are among the most advanced and reliable on the market.

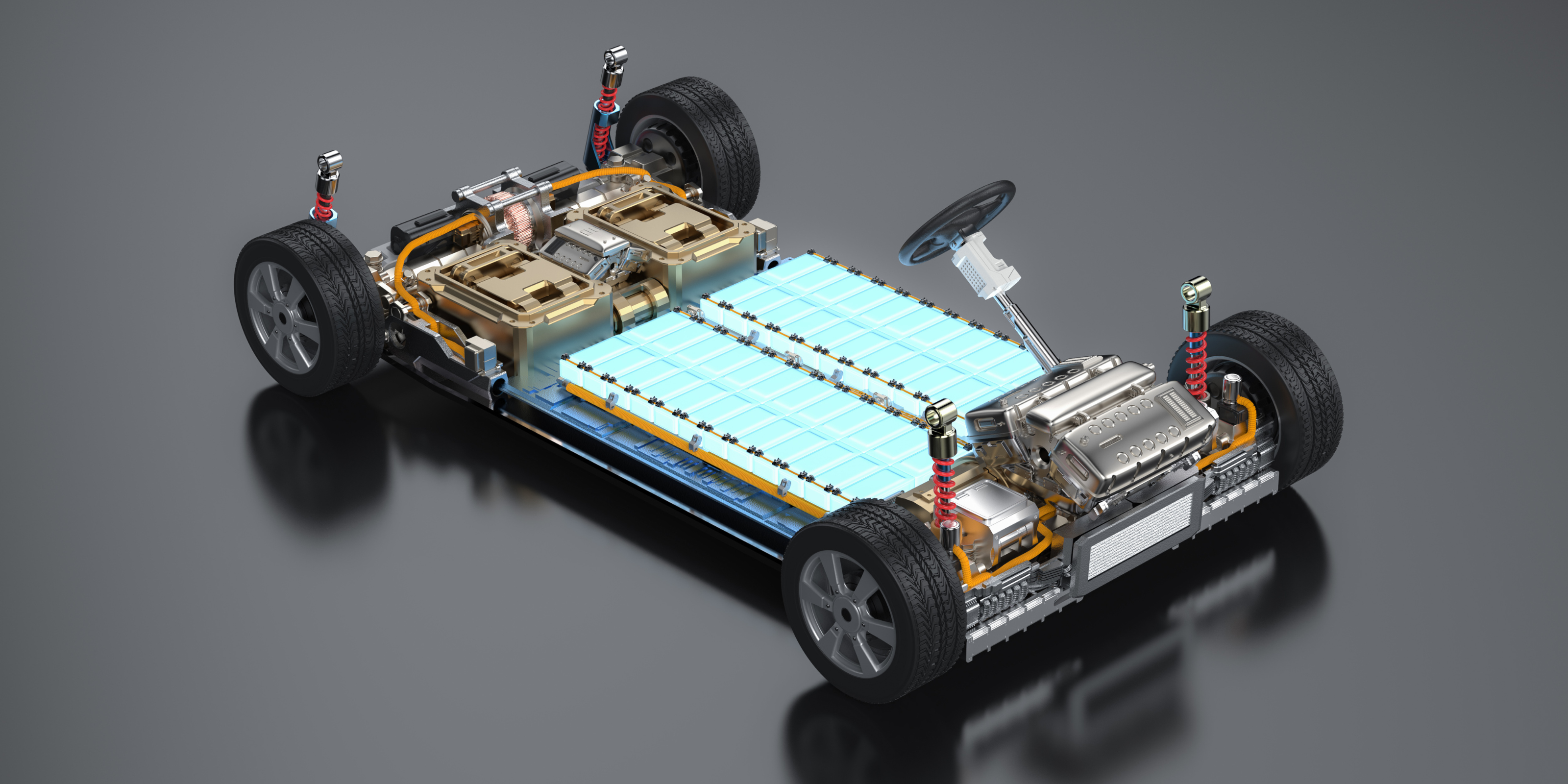

Electric Vehicles Batteries

Lithium Battery Company is committed to delivering customized lithium-ion battery solutions that meet the unique requirements of electric vehicle manufacturers. Our team of experts collaborates with manufacturers to develop custom battery packs that are tailored to their specific applications, ensuring that every battery we produce meets the highest standards of performance and reliability.

Electronics Industry

As the demand for portable and mobile devices continues to grow in the electronics industry, lithium-ion batteries have become the go-to power source for many manufacturers. And with good reason. Lithium-ion batteries offer high energy density, longer lifespan, and faster recharge times compared to traditional lead-acid batteries. At Lithium Battery Company, we specialize in providing custom lithium-ion battery solutions for any application in the electronics industry. Our team of expert engineers can design and manufacture batteries that meet even the most demanding requirements.

Energy Storage Systems

Lithium Battery Company is committed to producing high-quality energy storage system lithium batteries (BESS) that exceed customer expectations. Our state-of-the-art fully automated manufacturing factory guarantees precision manufacturing that ensures consistent product quality. Delivering outstanding BESS requires accuracy, speed and efficiency, all ingredients incorporated into our manufacturing process. Our production team comprises highly trained personnel who work seamlessly with our world-class robotics and machinery, integrated with our Quality Management System to ensure defect-free products. The BESS range is customised to cater to a vast range of marine and off-grid applications.

Medical Devices

Lithium Battery Company has the expertise to manufacture top-quality lithium ion batteries for medical devices. Our batteries provide long-lasting, reliable power for critical medical equipment such as patient monitors, ventilators, and infusion pumps. Our advanced battery technology delivers higher energy density and greater efficiency, resulting in reduced weight and longer operating time for medical devices. Additionally, our batteries are built to withstand extreme conditions and have built-in safety features such as temperature sensors and circuit protection, ensuring the utmost reliability and safety for patients and medical professionals alike. Lithium Battery Company understands the importance of providing the best solutions for the medical industry, and we are committed to producing high-performance lithium ion batteries that meet the rigorous standards of medical equipment manufacturers.

Aerospace and Defense

As a leading supplier of lithium ion batteries, Lithium Battery Company is well-positioned to provide bespoke battery solutions for the Aerospace and Defense industries. Our lithium ion batteries are highly adaptable, lightweight and possess exceptional energy density making them ideal for the demanding requirements of aerospace and defense applications. We have a comprehensive in-house research and development team, coupled with a state-of-the-art manufacturing facility that can cater to complex battery designs and applications. Our manufacturing processes adhere to strict quality standards that ensure the batteries we produce are safe, reliable, and function optimally in the harshest environments. We have a proven track record in developing batteries that possess high cycle life in extreme operating conditions, making them ideal for applications such as Unmanned Aerial Vehicles (UAVs), Ground Support Equipment, and tactical communication systems. We take pride in offering high-grade lithium ion batteries that are dependable, robust, and meet the stringent requirements of aerospace and defense industries.

Railway Industry

Lithium Battery Company has already made significant strides in producing high-quality lithium ion batteries for various applications. However, the company can further expand its manufacturing capabilities to cater to the railway industry. Lithium ion batteries have the potential to completely revolutionize the railway industry. The batteries offer a longer lifespan, higher energy density, and increased efficiency compared to traditional lead-acid batteries. Additionally, lithium ion batteries are lighter in weight, fitting well with the needs of the railway industry where weight is a critical issue. Given these benefits, Lithium Battery Company can take advantage of the untapped potential of the railway industry and manufacture lithium ion batteries specifically designed for railway applications. By doing so, Lithium Battery Company can provide efficient energy solutions for this sector, ultimately contributing towards the future sustainability of the railway industry.

Motorhome / RV

Lithium Battery Company is well poised to manufacture top-of-the-line lithium ion batteries for Motorhomes and RVs. Our battery technology is designed to provide longer-lasting and more reliable power solutions to marine enthusiasts who seek to maximize their on-the-water experience. We use advanced lithium ion technology that guarantees faster charging times, higher energy density, and seamless performance in extreme weather conditions. Our manufacturing process is designed to comply with the highest safety standards and regulations of the marine industry. We offer flexible battery sizes, and our batteries can be easily integrated into the existing electrical systems of Motorhomes and RVs. With Lithium Battery Company, marine enthusiasts can expect efficient and durable power solutions that will take their on-water experience to the next level.

Marine / Boats

Lithium Battery Company is a leading manufacturer of high-quality lithium ion batteries that are now optimized for marine use. Our expertise in battery technology enables us to deliver powerful and reliable marine lithium batteries that are specifically designed to serve as house batteries for boats. Our lithium ion batteries boast impressive performance, longevity, and are perfectly suited for marine environments, ensuring that boaters can rely on the unwavering supply of power.

In addition, we are also proud to offer the most advanced Trolling Motors battery, built with cutting-edge technology. Our Trolling Motors batteries are designed to provide boaters with a superior boating experience, delivering long-lasting power and peak performance.

Telecommunications

Lithium Battery Company has established itself as a leading manufacturer of lithium ion batteries for various applications. In response to the growing demand for high-performance batteries in telecommunication, we have developed a cutting-edge technology that allows us to manufacture reliable and long-lasting batteries for this industry. Our lithium ion batteries are designed to meet the specific requirements of telecommunication applications, providing enhanced safety, extended lifespan, and excellent energy density. We use only high-quality materials and advanced manufacturing processes to ensure that our batteries perform consistently and meet or surpass the industry's rigorous standards. With our expertise in lithium ion battery technology and our commitment to quality, we are confident that we can offer the best battery solutions for telecommunication companies looking for reliable and efficient power sources. Let us help your business stay connected and powered by choosing our lithium ion batteries for your telecommunication applications.

Specialized Lithium Battery Packs

In today's increasingly mobile world, the need for reliable and efficient custom lithium battery packs has never been more critical. Whether it's powering medical devices, smart homes, or electric vehicles, lithium-ion technology delivers lightweight, high-energy density that's unmatched by other batteries. With custom lithium battery packs, you can optimize performance, capacity, and safety to suit your specific needs. Not all lithium-ion batteries are created equal, and a custom lithium battery pack can ensure that the design aligns with your unique needs.

Trusting an expert in designing and manufacturing your custom lithium battery pack is essential to ensuring ultimate performance and longevity. Li-ion technology is the way of the future, and custom battery solutions are the key to keeping up with ever-changing demands.

Get the Right Shape, Size & Capacity for Any Application

Check out our collections of 12V Lithium Ion Batteries, 12V Lithium PVC Wrapped Batteries, 24V Lithium Batteries, 36V Lithium Batteries, 48V Lithium Batteries, 72V Lithium Batteries, 96V Lithium Batteries, 115V Lithium Batteries, 128V Lithium Batteries, 144V Lithium Batteries, 206V Lithium Batteries, 288V Lithium Batteries, 320V Lithium Batteries, 350V Lithium Batteries, 400V Lithium Batteries, 537V Lithium Batteries, 614V Lithium Batteries, or BUILD YOUR OWN CUSTOM BATTERY PACK!

Batteries Any Shape Or Size

- Design the perfect battery to power your project

- Get the exact lithium battery you need, custom-made

- Unlock a reliable source of energy with Lithium Battery Company

- Cut through power outages & create long-lasting solutions

- Unleash remarkable innovations with tailored batteries

Custom Tailored BMS

- Unlock the full potential of your lithium battery

- Recharge your battery in minutes with our custom tailored system

- Get maximum power and performance from Lithium Battery Co

- Keep your devices running longer with our advanced BMS technology

Long-Lasting and Fast-Charging

- Get the power you need with our long-lasting lithium batteries

- Say goodbye to short battery life - Fast charge your device now

- Make sure you don't miss out on a moment - Invest in LBC

- The best value and performance for all of your devices

High Energy Density

- Power your Devices with Long Lasting Lithium Batteries

- Outperform Other Batteries With High Energy Density Technology

- Keep Your Battery Charged For Days On End

- Get The Latest In Cutting Edge Battery Technology Now

Resilience and Sustainability

- Get the Power You Need with Our Lithium Batteries

- The Most Reliable Solution for All Your Energy Needs

- Invest in Resilience and Sustainability

- Find Sustainable Solutions with Ease and Confidence

Scalable Capacity

- The Most Powerful Battery for Your Business

- Get Unlimited Power & Scalable Capacity with Lithium Batteries

- Unlock Unmatched Performance and Reliability with our State of the Art Technology

- Unleash your Innovative Edge Today with the Future of Battery Technology

Advanced Performance

- Power up with the most advanced lithium batteries

- Unlock a new level of performance with Lithium Battery Company

- Get reliable, long lasting power for your devices

- Upgrade to lithium and join millions of users who trust us

Cost-Effective Production

- Get the power to do more with Lithium Battery Company

- Wave goodbye to battery-related woes with our reliable solutions

- Cost effective lithium batteries for production needs

- Our quality standards are unbeatable - Experience them today!

Communication with External Devices

- Power your projects with long-lasting, reliable lithium batteries

- Take control of your external devices with Lithium Battery Co

- Get the most out of your communication needs

- The #1 tool trusted by top tech companies globally

- Boost efficiency for longer battery duration

Fault Diagnosis and Reporting

- Get the reliable, fault-free power supplies you need

- Uncover hidden faults with Lithium Battery Co's reporting system

- Diagnose and report quickly and accurately

- Make sure your lithium battery is working optimally with our diagnosis tools

Lithium Ion Batteries FAQ

Lithium Battery Company is dedicated to providing innovative and reliable battery solutions to power the world. Our batteries are designed to meet the unique needs of a variety of applications while striving for energy efficiency, environmental stewardship and safety. We have a mission to provide superior sustainable battery solutions that make modern life possible while also creating a better future for generations to come. Our vision is to revolutionize the way people use energy by advancing technology through our commitment to sustainability and excellence in customer service.

What types of lithium batteries do you offer?

At Lithium Battery Company, we offer a wide range of lithium batteries for all types of applications and devices. Our lithium batteries use various technologies such as LiFePO4 (lithium iron phosphate) and Lithium-ion NMC cells (nickel metal cobalt). We have the capability to create custom battery packs in a variety of voltages from 3V up to 400V.

How do your lithium batteries compare to other brands?

When shopping for lithium batteries, you will find a variety of brands and types available. There is no one-size-fits-all answer as to which brand or type works best for your needs.

However, when it comes to quality control, we can confidently say that our lithium batteries stand out from the rest in terms of quality and reliability. That's because at every step in the production process – from sourcing the best raw materials to packing them carefully before shipment – we take extra precautions to ensure our batteries are of the highest possible standards.

What safety measures do you take to ensure the quality and safety of your products?

At Lithium Battery Company, we take a number of steps to ensure the quality and safety of our products. As a leading manufacturer of lithium-ion battery products, we prioritize safety above all else.

First and foremost, our manufacturing processes are strictly regulated according to ISO 9001 standards for quality management systems. This includes rigorous inspection procedures that check raw materials against strict specifications before they enter the production line. We also have an in-line monitoring system that examines each component during assembly for any potential defects or faulty connections.

How reliable are your lithium batteries?

Lithium Battery Company's batteries are renowned for their reliable performance. We have been in the lithium battery business for many years, supplying to some of the world’s leading companies such as SpaceX, Google, and General Dynamics. Battery storage technology is a critical component of modern life and our cells meet the needs of Fortune 50 companies because we put a premium on safety and reliability.

Do you offer any warranty for your products?

Yes, we do offer warranties for our products. Our warranty coverage ranges from 1 to 11 years, depending on the battery pack and its application use.

We understand that the trust you place in our products is crucial so we strive to provide a comprehensive warranty package with all of our batteries. Each product contains a specific guide outlining exactly what coverage your purchase provides - this includes repair and/or replacement if required and extends to periodical maintenance required over time.

Lithium Battery News

Powering the Future: The Evolution of Electric Vehicle Batteries

Electric vehicles (EVs) are not just a mode of transportation; they represent a monumental shift towards sustainable mobility and environmental consciousness. At the heart of every EV lies its batt...

Revolutionizing Energy Storage: How Lithium Battery Company Utilizes Top Lithium-Ion Battery Innovations in 2024 At Lithium Battery Company, we are committed to pushing the boundaries of energy s...

The Ultimate Guide to Choosing the Best LiFePO4 Battery

LiFePO4 batteries have transformed the energy storage landscape, offering a delicate balance of power, safety, and sustainability. However, choosing the best LiFePO4 battery is not a one-size-fits-...