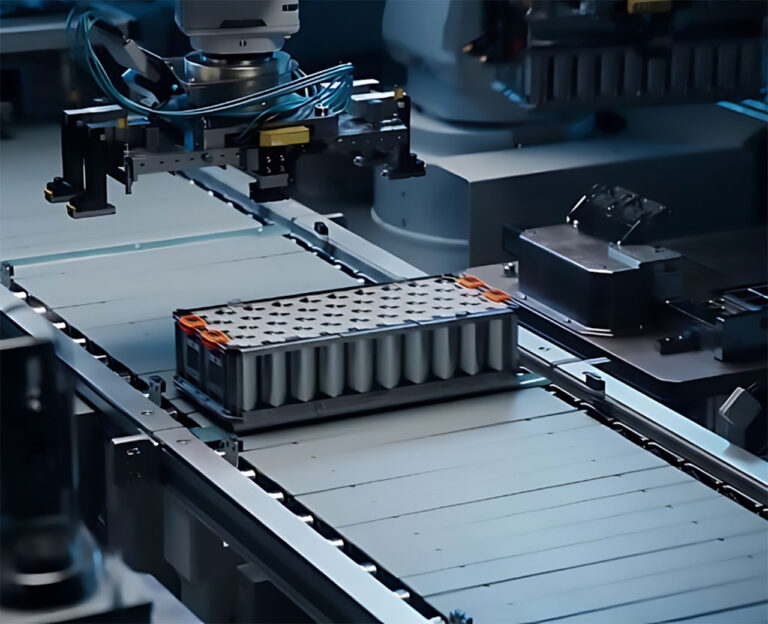

Reliability, safety, and efficiency are non-negotiables when it comes to industrial machinery. Traditionally, diesel engines and lead-acid batteries have supplied that power, but their limitations are becoming harder for industries to ignore. Lithium battery technology has emerged as a game-changing alternative, offering higher energy density, longer cycle life, and safer operation. By replacing outdated systems with advanced lithium power, companies can achieve greater efficiency, lower long-term costs, and improved sustainability.

Efficiency and Productivity Gains

For industries where uptime drives profitability, efficiency is everything. Lithium batteries have a higher energy density, allowing machinery to run longer on a single charge. Unlike lead-acid systems, which require lengthy charging and cool-down, lithium battery packs charge outperform legacy power sources by providing higher energy density, faster charging, and minimal maintenance.

In warehouses, this means forklifts can operate for longer hours without needing to charge or swap batteries. On construction sites, equipment can return to service faster, minimizing costly downtime. For industries competing on speed and efficiency, lithium power gives operators a distinct edge.

Safety and Reliability in Harsh Environments

Industrial machinery often operates under extreme conditions, like high temperatures, vibration, dust, and heavy loads. Lithium batteries are engineered to withstand these environments while delivering consistent performance.

A critical factor is the integration of Battery Management Systems (BMS). These advanced controls monitor voltage and temperature across cells, preventing overcharging and equipment failure. LBC’s packs integrate advanced Battery Management Systems (BMS) with features like cell balancing, CANBus/RS485 communication, and built-in thermal protection to ensure safe operation under extreme industrial loads.

For operators, this means safer work sites and equipment that can be trusted to perform under stress. Compared to diesel systems that emit fumes and noise or lead-acid batteries that risk acid leaks, lithium packs provide a cleaner, safer, and more reliable solution.

Lower Lifecycle Costs

Upfront, lithium systems may cost more than lead-acid batteries or diesel engines. However, when evaluating the total cost of ownership, lithium quickly proves to be the more cost-effective option.

- Long Cycle Life: Lithium batteries deliver thousands of charge-discharge cycles, lasting up to 4–6 times longer than lead-acid alternatives.

- Reduced Downtime: Fewer replacements and less maintenance mean machines spend more time operating.

- Operational Savings: Lower energy waste and fewer service hours reduce long-term expenses.

For fleet operators managing dozens or hundreds of machines, these savings compound quickly. Lithium power transforms energy storage from a recurring cost into a long-term investment.

Sustainability and Compliance

Industries worldwide are under increasing pressure to reduce emissions and adopt sustainable practices. Lithium batteries help meet these goals by providing:

- Zero On-Site Emissions: Unlike diesel engines, lithium systems produce no harmful exhaust.

- Quieter Operation: Reduced noise pollution creates safer, more comfortable work environments.

- Regulatory Alignment: Many regions are phasing out high-emission systems; lithium helps operators stay compliant.

For companies seeking to balance performance with environmental responsibility, lithium technology provides a practical, future-proof path forward.

U.S.-Based Manufacturing Advantage

Supply chain resilience has become critical in today’s industrial landscape. Relying on overseas battery suppliers exposes companies to unpredictable shipping delays and quality concerns. By partnering with a U.S.-based manufacturer like Lithium Battery Company, industrial operators gain access to faster delivery times, trusted compliance, and more customization options.

LBC’s Foreign Trade Zone (FTZ) designation also provides flexibility for international OEMs while anchoring advanced battery manufacturing securely in the United States.

Comparison: Traditional Power vs. Lithium Systems

| Factor | Lead-Acid/Diesel Systems | Lithium Battery Systems |

| Runtime Efficiency | Short cycles, frequent downtime | Long runtimes, fast charging |

| Maintenance | Regular service and fluid checks | Minimal maintenance required |

| Safety | Risk of spills, fumes, and noise | Integrated BMS, clean and safe |

| Lifecycle Cost | Lower upfront, high long-term | Higher upfront, lower lifecycle cost |

| Sustainability | High emissions, noisy | Cleaner, quieter, regulatory-friendly |

From warehouses and factories to construction sites and mines, lithium batteries are revolutionizing industry. With longer runtimes, faster charging, safer operation, and lower lifecycle costs, they deliver the performance and reliability industries need to stay competitive.

Lithium Battery Company is proud to support this industrial transformation. With advanced U.S.-based manufacturing, customizable designs, and rigorous quality testing, LBC provides heavy equipment operators and OEMs with the energy storage systems they can trust.

Partner with Lithium Battery Company!

For industrial partners seeking durable, efficient, and future-ready power solutions, Lithium Battery Company is the U.S.-based partner powering the next generation of heavy-duty equipment. Contact us today to learn more.