In a recent episode of the All-In podcast titled “Winning the AI Race Part 1”, hosts Chamath Palihapitiya, Jason Calacanis, David Sacks, and David Friedberg brought together an impressive lineup of guests. These included Michael Kratsios (Director of the Office of Science and Technology Policy), Kelly Loeffler (Administrator of the Small Business Administration), and industry leaders from Palantir, Y Combinator, Hadrian, and Gecko Robotics. Their conversation centered on a critical question: How can America maintain its competitive edge in the global AI race?

The answer, as it turns out, might be unfolding right now in an unassuming 85,000 square foot facility in South Tampa, Florida. Here, Lithium Battery Company is building something remarkable. They’re creating a fully automated lithium battery manufacturing facility that represents exactly the kind of AI-driven innovation the podcast guests were advocating for.

The Tampa Revolution: Where AI Meets Manufacturing

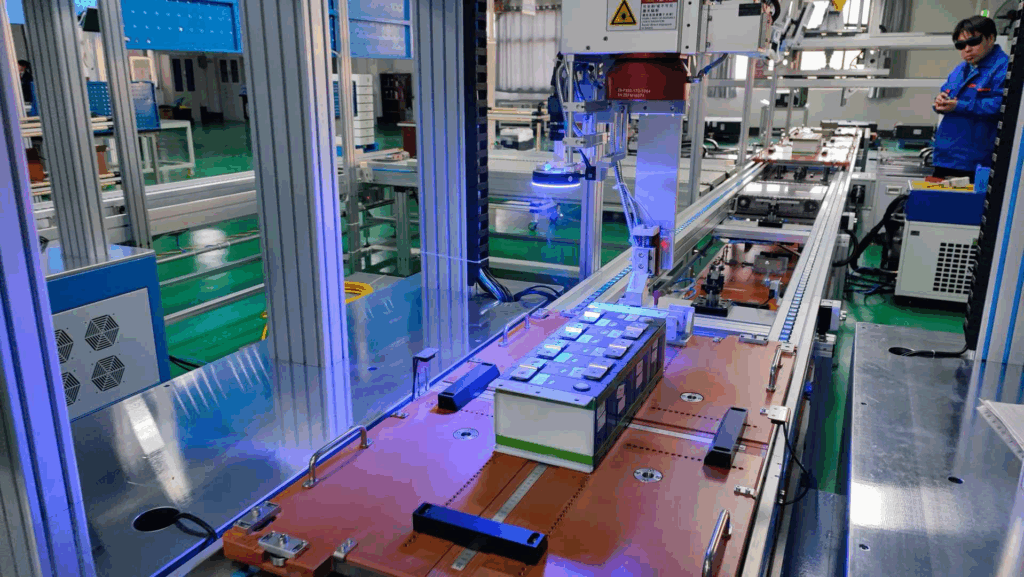

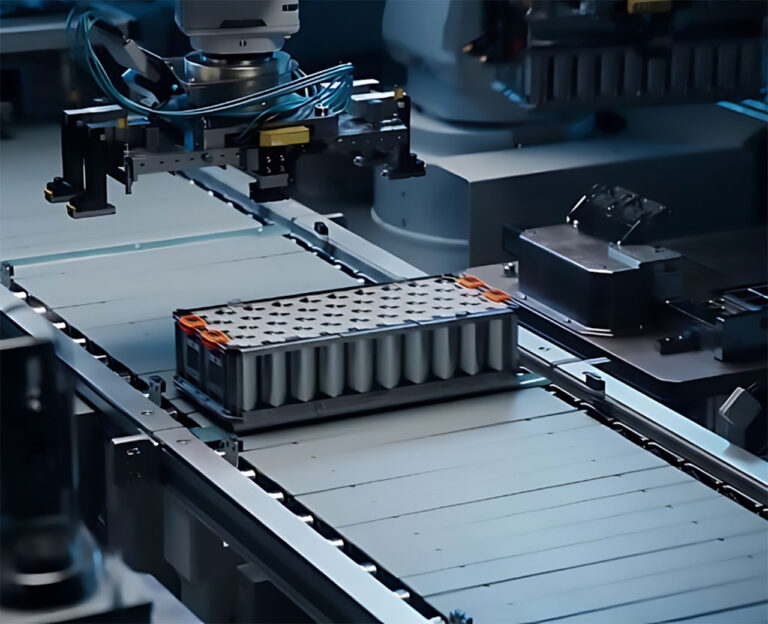

Lithium Battery Company’s $4 million investment in Tampa represents more than just another manufacturing facility. Instead, it’s a microcosm of the broader AI revolution that the All-In podcast guests were discussing. The company has established what they call “the nation’s first all-in-one battery pack factory.” This facility features fully automated production lines for both cylindrical and prismatic lithium battery packs.

This isn’t just automation for automation’s sake. The facility incorporates cutting-edge AI technologies that directly address the themes raised in the podcast. When Paul Buchheit from Y Combinator spoke about the importance of AI in maintaining competitive advantages, he could have been describing exactly what’s happening in Tampa. The facility’s AI-powered systems enable predictive maintenance, real-time quality control, and intelligent production optimization. These capabilities are transforming battery manufacturing from a labor-intensive process into a precision-driven, technology-enabled operation.

The timing is particularly significant. As Kelly Loeffler discussed the Small Business Administration’s role in supporting American innovation, companies like Lithium Battery Company are proving that advanced manufacturing can return to American shores. This isn’t happening through protectionism, but through technological superiority. The Tampa facility is designed to serve both civilian and military applications, addressing the national security concerns that were a recurring theme throughout the podcast discussion.

The AI Advantage: Beyond Simple Automation

What makes the Tampa facility particularly relevant to the All-In podcast’s discussion is how it exemplifies the difference between traditional automation and AI-driven manufacturing. As Shyam Sankar from Palantir emphasized during the podcast, the real power of AI lies not in replacing human workers. Instead, it lies in augmenting human capabilities and creating entirely new possibilities.

The battery manufacturing process at Lithium Battery Company demonstrates this principle in action. Traditional battery manufacturing requires extensive manual quality control, with human inspectors checking for defects that could compromise safety or performance. In contrast, the Tampa facility’s AI systems can detect microscopic flaws in real-time. They analyze thousands of data points per second to ensure consistent quality while dramatically reducing waste and production time.

This approach aligns perfectly with the podcast guests’ emphasis on AI as a tool for American competitiveness. Michael Kratsios, speaking from his role in the Office of Science and Technology Policy, highlighted how AI technologies can help American companies compete. They compete not just on cost, but on quality, innovation, and speed to market. The Tampa facility embodies this strategy, using AI to achieve levels of precision and efficiency that would be impossible with traditional manufacturing methods.

Strategic Implications: The New Manufacturing Paradigm

The conversation between Chris Power from Hadrian and Jake Loosararian from Gecko Robotics during the podcast touched on a crucial point. America’s manufacturing renaissance isn’t just about bringing jobs back. Rather, it’s about reimagining what manufacturing can be in the AI age. The Tampa facility illustrates this transformation perfectly.

Lithium Battery Company’s decision to implement their “Reshore AI” initiative demonstrates the kind of strategic thinking that the podcast guests were advocating. By combining AI-driven automation with smart manufacturing processes and advanced reshoring strategies, the company is creating a competitive advantage that goes beyond simple cost considerations. The facility can import raw materials efficiently while maintaining the “Made in America” value proposition that increasingly matters to both government and commercial customers.

This approach directly addresses concerns raised during the podcast about America’s ability to compete with lower-cost manufacturing centers. Rather than trying to match labor costs, the Tampa facility leverages AI to achieve superior quality, faster delivery times, and greater customization capabilities. It’s a perfect example of what David Sacks meant when he discussed the importance of technological differentiation in global competition.

The facility’s focus on both civilian and military applications also reflects the dual-use nature of AI technologies that was a recurring theme in the podcast. The same AI systems that optimize battery production for electric vehicles can be adapted for defense applications. This creates synergies that strengthen both commercial competitiveness and national security.

The Ripple Effect: Beyond Battery Manufacturing

What makes the Tampa story particularly compelling in the context of the All-In podcast is how it demonstrates the broader implications of AI adoption in manufacturing. The facility isn’t just producing batteries. Instead, it’s producing a new model for American industrial competitiveness that other companies and industries can emulate.

The 50 high-tech jobs that Lithium Battery Company plans to create over the next three years represent exactly the kind of employment opportunities that the podcast guests were discussing. These aren’t traditional manufacturing jobs. Rather, they are positions that require workers to collaborate with AI systems, manage automated processes, and continuously optimize production parameters. It’s a vision of the future workforce that combines human creativity and problem-solving with AI-powered efficiency.

The facility also serves as a testing ground for emerging technologies that could transform other industries. Digital twin technology, which creates virtual replicas of physical production processes, allows engineers to optimize operations without disrupting actual production. AI-powered predictive maintenance systems can identify potential equipment failures before they occur, minimizing downtime and maximizing efficiency. These innovations have applications far beyond battery manufacturing, from aerospace to pharmaceuticals to consumer electronics.

The Convergence of Trends: Energy, AI, and National Strategy

The Tampa facility sits at the intersection of several trends that the All-In podcast guests identified as critical to America’s future competitiveness. The global transition to renewable energy is driving unprecedented demand for advanced battery storage solutions. At the same time, the increasing sophistication of AI technologies is making it possible to manufacture these complex products with levels of precision and efficiency that were unimaginable just a few years ago.

This convergence is particularly relevant to the national security discussions that featured prominently in the podcast. Battery technology is increasingly recognized as a critical component of both civilian infrastructure and military capabilities. By establishing advanced manufacturing capabilities on American soil, companies like Lithium Battery Company are helping to reduce dependence on foreign supply chains. They’re also building the industrial base needed to support both economic growth and national defense.

The facility’s emphasis on both cylindrical and prismatic battery formats also demonstrates the kind of technological flexibility that the podcast guests emphasized as crucial for maintaining competitive advantages. Rather than optimizing for a single product or market, the AI-driven production systems can adapt to different battery chemistries, form factors, and performance requirements as market demands evolve.

Lessons for the Broader AI Race

The success of Lithium Battery Company’s Tampa facility offers several important lessons for other companies and policymakers thinking about how to win the AI race that the All-In podcast explored in depth.

First, AI adoption in manufacturing isn’t just about efficiency. It’s about creating entirely new competitive advantages that are difficult for competitors to replicate. The combination of advanced algorithms, proprietary data, and optimized processes creates barriers to entry that go far beyond traditional manufacturing economics.

Second, the most successful AI implementations combine technological innovation with strategic business positioning. Lithium Battery Company’s “Reshore AI” initiative, focus on dual-use applications, and emphasis on American manufacturing creates multiple layers of competitive advantage that reinforce each other.

Third, the transition to AI-driven manufacturing requires new types of workforce development and organizational capabilities. The 50 high-tech jobs being created in Tampa represent a new category of manufacturing employment that requires different skills and offers different career trajectories than traditional factory work.

Finally, the national security implications of AI-driven manufacturing extend far beyond individual companies or industries. By demonstrating that advanced manufacturing can be both economically viable and strategically valuable on American soil, facilities like the Tampa plant are helping to rebuild the industrial base that underpins both economic prosperity and national security.

The Road Ahead: From Podcast to Practice

As the All-In podcast guests made clear, winning the AI race isn’t just about developing better algorithms or attracting more investment. It’s about translating technological capabilities into real-world competitive advantages. The Lithium Battery Company facility in Tampa provides a compelling example of how this translation can work in practice.

The facility represents more than just another manufacturing investment. It’s a proof of concept for a new model of American industrial competitiveness that combines AI-driven efficiency with strategic positioning and workforce development. As other companies and industries grapple with the challenges and opportunities of AI adoption, the Tampa facility offers valuable lessons about how to move from concept to implementation.

The conversations featured in the All-In podcast provide the strategic framework for understanding why these developments matter. The Tampa facility provides a concrete example of how that framework can be applied to create lasting competitive advantages. Together, they point toward a future where American companies don’t just participate in the global AI race. They help define what winning looks like.

For business leaders, policymakers, and investors thinking about America’s role in the global AI competition, the message is clear. The race isn’t just being won in Silicon Valley boardrooms or Washington policy meetings. It’s being won in places like Tampa, where innovative companies are using AI to reimagine what American manufacturing can achieve in the 21st century.

References and Additional Resources

Podcast Resources

- All-In Podcast Episode: “Winning the AI Race Part 1”

- All-In Podcast Website: All-In with Chamath, Jason, Sacks & Friedberg

- Episode Webpage: Libsyn Episode Page

Lithium Battery Company Resources

- Company Website: lithiumbatterycompany.com

- Tampa Expansion Announcement: LBC $4M Tampa Expansion

- Manufacturing Returns to US: Tampa Battery Company Manufacturing Returns

- Facility Expansion News: LBC Tampa Expansion

Follow the All-In Podcast

- X (Twitter): @theallinpod

- Instagram: @theallinpod

- TikTok: @theallinpod

- LinkedIn: All-In Podcast

Follow the Hosts

- Chamath Palihapitiya: @chamath

- Jason Calacanis: @Jason

- David Sacks: @DavidSacks

- David Friedberg: @friedberg