Electric vehicles (EVs) are reshaping the future of transportation, making up 20% of new car purchases. The rapid adoption of EVs is driven by a combination of government incentives, growing interest in sustainability, and increasing consumer demand for innovative transportation solutions. These high-tech vehicles rely on battery systems that determine how far the car can travel, how safe it is, and how reliable it is. Lithium batteries are the preferred solution thanks to their high energy density, long cycle life, and advanced safety features.

Why Safety is Critical in EV Batteries

Safety is one of the most important considerations in EV battery design. Lithium batteries store large amounts of energy, and if improperly managed, risks such as thermal runaway can occur. Thermal runaway is a chain reaction where excessive heat can trigger fire or failure. Thermal stability is crucial for safe EV operation.

Modern lithium chemistries and engineering techniques have made EV batteries far safer than ever before. Lithium Iron Phosphate (LFP) batteries, for example, are known for their thermal stability and resistance to overheating. Additionally, Nickel Manganese Cobalt (NMC) packs rely on advanced battery management systems (BMS) to maintain safe operating conditions while still delivering high-density energy.

Enhancing Performance in Electric Vehicles

Beyond safety, performance is a defining factor in EV adoption. Consumers want longer ranges with shorter charging times. Consumers are also looking for EVs with batteries that will last without major degradation.

Lithium batteries excel in these areas, offering:

- High Energy Density: Enabling longer driving ranges without increasing vehicle size or weight.

- Fast Charging Capabilities: Reducing downtime and improving convenience for EV drivers.

- Extended Cycle Life: Allowing batteries to endure thousands of charge and discharge cycles, improving long-term value.

For example, NMC batteries are often used in passenger EVs to maximize range and power output. LFP batteries, on the other hand, provide unmatched cycle life and enhanced safety, making them ideal for fleet vehicles, buses, and applications where longevity is prioritized.

LFP vs. NMC: Choosing the Right Chemistry for EVs

Not all EV batteries are created equal. The choice between LFP and NMC depends on the specific goals of the vehicle manufacturer.

| Feature | LFP Chemistry | NMC Chemistry |

| Safety | Very stable, low fire risk | Higher risk, requires BMS |

| Energy Density | Moderate | High |

| Cycle Life | Long-lasting | Shorter, but improving |

| Cost | Lower | Higher |

| Applications | Buses, fleets, safe-use cases | Passenger EVs, performance EVs |

By understanding these trade-offs, OEMs can design vehicles that meet the needs of their customers while ensuring reliability. Lithium Battery Company has expertise in both chemistries, ensuring that each solution is engineered to maximize value for its intended application.

The Role of Battery Management Systems (BMS)

An advanced Battery Management System (BMS) is essential to enhancing both safety and performance in EV batteries. BMS technology continuously monitors cell voltage, temperature, and state of charge to prevent risks such as overcharging, deep discharge, and overheating, keeping consumers and manufacturers safe. For EVs, a high-quality BMS ensures that each battery cell operates within safe parameters and that energy is balanced across the pack for maximum efficiency.

U.S.-Based Manufacturing Advantage for EV OEMs

Supply chain stability is as critical as the batteries themselves. Many automakers face challenges with overseas suppliers, from shipping delays to geopolitical disruptions. Working with a U.S.-based partner eliminates these risks while ensuring faster delivery and tighter quality control.

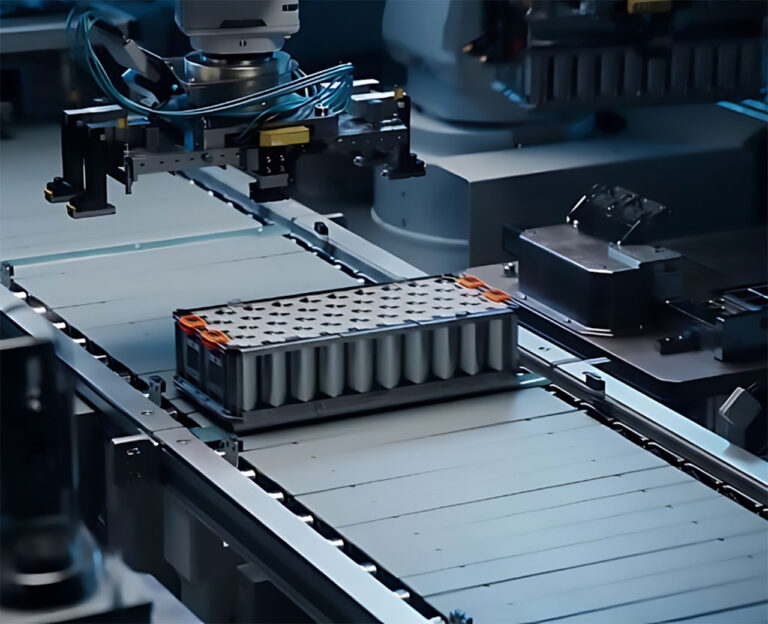

At Lithium Battery Company’s 60,000-square-foot automated facility in Tampa, Florida, OEMs benefit from semi-automated assembly lines, cleanroom environments, and advanced robotics. This allows for consistent quality at scale, whether producing small-batch prototypes or high-volume production runs. The facility’s Foreign Trade Zone (FTZ) designation also enables streamlined collaboration with international OEM partners, while keeping core manufacturing anchored in the United States.

Ultimately, lithium batteries are the foundation of the EV revolution, combining advanced safety features with performance metrics that meet the expectations of modern drivers. With chemistries like LFP and NMC, supported by intelligent BMS systems and rigorous testing, they provide the reliability that OEMs and consumers alike demand.

Partner with Lithium Battery Company!

For OEMs and automakers seeking tailored, high-performance EV battery solutions, Lithium Battery Company is the U.S.-based partner to power safer, smarter, and more reliable vehicles. Contact us today to learn more about EV batteries.