Original Equipment Manufacturers (OEMs) across industries are driving innovation in transportation, energy, healthcare, defense, and beyond. With growing innovation in these industries comes a growing need for reliable energy. The market for industrial lithium batteries is projected to triple in the next ten years, underscoring the need for reliable, high-performance battery systems that integrate seamlessly into their products. OEMs must work with a battery manufacturer that understands their unique requirements, offers flexible customization, and delivers solutions backed by rigorous testing and automation. Lithium Battery Company (LBC), with its state-of-the-art U.S. facility in Tampa, Florida, specializes in helping OEMs achieve these goals by combining engineering expertise, scalable production, and trusted integration capabilities.

Understanding OEM Needs

Every OEM project begins with specific technical and performance requirements. From electric vehicles to medical equipment, different manufacturers need different batteries in terms of voltage, chemistry, and design. Some applications require high energy density for long runtimes, while others prioritize safety or cycle life.

Lithium Battery Company addresses this by offering a range of chemistries, including LFP, NMC, and sodium-ion, as well as flexible formats, including cylindrical and prismatic cells. This versatility allows OEM partners to select the best fit for their application. By starting with an in-depth consultation, LBC ensures every solution is aligned with the operational environment and long-term goals of the OEM.

Custom Engineering and Design Collaboration

Partnerships with lithium battery companies extend beyond supplying off-the-shelf packs. Successful collaborations focus on co-designing solutions that meet precise performance, safety, and integration needs.

At LBC, engineering teams work alongside OEM partners to develop battery packs optimized for each application. This includes form factor adjustments, thermal management design, and more. For example, defense applications may demand ruggedized systems that withstand vibration and temperature extremes, while healthcare partners may need compact, lightweight packs for sensitive medical devices.

By tailoring every aspect of the design process, LBC ensures batteries are not just functional but purpose-built to enhance the end product.

Seamless Integration into OEM Systems

Integrating batteries into OEM systems requires more than physical compatibility; it demands rigorous testing to ensure reliable performance under real-world conditions.

Lithium Battery Company conducts comprehensive quality assurance at its Tampa facility, validating that every pack integrates seamlessly with OEM hardware and software. This process includes environmental testing, cycle testing, and system-level compatibility assessments. For applications like data centers and telecommunications, where even a momentary disruption can have significant consequences, this level of testing ensures that power systems perform flawlessly when needed most.

Seamless integration also allows OEMs to reduce time-to-market, as they can trust that their energy systems will work consistently without extensive reengineering.

Scalable Manufacturing for Growth

OEM partnerships are built on trust, and scalability is one of the most important elements of that relationship. As OEMs expand, they need assurance that their energy storage partner can grow alongside them.

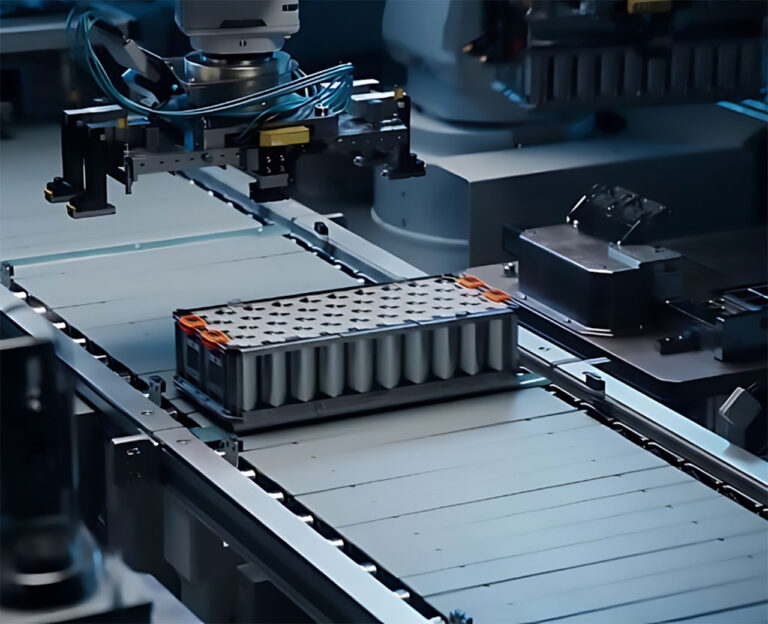

With its 60,000-square-foot automated facility, LBC delivers on this promise. Semi-automated assembly lines, cleanroom production, and advanced robotics ensure consistency and efficiency at scale. Whether producing small runs for specialized projects or ramping up for large-volume orders, LBC’s systems are designed to maintain high standards while meeting demand.

Additionally, the facility’s Foreign Trade Zone (FTZ) designation provides flexibility for global OEM partnerships, streamlining international logistics while keeping core manufacturing anchored in the United States.

Long-Term Support and Reliability

True OEM partnerships don’t end after battery delivery. Long-term success depends on ongoing collaboration, lifecycle support, and consistent supply continuity.

Lithium Battery Company provides its partners with reliability that extends beyond the initial project. With domestic production, OEMs gain stability against global supply chain disruptions and greater confidence in delivery schedules. Continuous quality monitoring and product refinement further ensure that systems remain effective throughout their lifecycle. This approach allows OEMs to focus on innovation while trusting that their energy storage partner will provide consistent performance and dependable support for years to come.

In an era where energy storage underpins nearly every major industry, OEMs need a partner that understands their vision, supports their growth, and ensures seamless integration. From design flexibility to scalable production and long-term support, lithium battery companies that prioritize OEM collaboration help shape the success of the products and systems they power.

Lithium Battery Company stands out as a leader in this space, providing custom-engineered, U.S.-manufactured solutions that meet the evolving needs of industrial, medical, defense, renewable, and technology sectors. By combining automation, rigorous testing, and a commitment to partnership, LBC delivers the reliability and innovation OEMs require.

Partner with Lithium Battery Company!

For OEMs seeking a trusted partner to integrate advanced lithium battery solutions, Lithium Battery Company provides the expertise and long-term reliability to power the future.