The rapid growth of electric vehicles (EVs) depends on safe, reliable, and high-performing batteries. Today, lithium-ion technology powers nearly every EV, delivering more than 770 GWh of deployed capacity.

Yet, this momentum presents persistent challenges, such as thermal runaway risks, global supply chain vulnerabilities, and the ever-present tradeoff between energy density and safety. For OEMs, fleet operators, and industrial partners, balancing performance with safety is mission-critical.

Safety Risks and Industry Response

The primary safety risk associated with lithium-ion batteries is thermal runaway, a chain reaction of heat that can escalate into a fire or explosion. Although EV fires are infrequent (occurring in fewer than 1 per 10 million battery cells), incidents tied to flooding, crashes, or improper charging can have serious consequences.

To address this, regulators and manufacturers are implementing more stringent testing, advanced fire suppression systems, and stronger disclosure requirements. At the same time, safer chemistries such as Lithium Iron Phosphate (LFP) are gaining traction as the preferred option for reducing risk.

LFP vs. NMC: Choosing the Right Chemistry for EV Batteries

Two chemistries dominate EV battery design: LFP (Lithium Iron Phosphate) and NMC (Nickel Manganese Cobalt). OEMs must weigh the tradeoffs between safety, cost, and performance.

| Feature | LFP (Lithium Iron Phosphate) | NMC (Nickel Manganese Cobalt) |

| Energy Density | ~150–205 Wh/kg | Up to ~300 Wh/kg |

| Cycle Life | 3,000–10,000 cycles | 1,000–2,300 cycles |

| Safety | Highly stable; low fire risk | Higher risk of abuse |

| Cost | Lower (cobalt-free) | Higher (contains cobalt/nickel) |

LFP batteries are the more intelligent choice for OEMs prioritizing safety, longevity, and cost efficiency. NMC batteries remain relevant where maximum energy density and extended range are the top priorities.

Balancing Performance and Safety

To deliver both safety and performance, modern EV battery systems integrate multiple layers of protection:

- Battery Management Systems (BMS) monitor voltage, temperature, and battery health in real-time to prevent critical issues.

- Thermal management via air or liquid cooling ensures stable operation and prolongs lifespan.

- Emerging technologies, especially solid-state batteries, are being developed to offer enhanced safety and density in the coming decade.

LBC Product Highlights: Tailoring Chemistry to OEM Needs

LBC’s 400 V 84 kWh LFP Battery Pack offers a compelling mix of safety, performance, and adaptability:

- High energy capacity (84 kWh) delivered via stable LFP chemistry

- Air-cooled design that operates reliably from –30°C to 50°C

- Built-in protections against overcharge, over-discharge, and short circuits

- Designed for electric buses, trucks, energy storage, and industrial equipment.

- This pack embodies the ideal for OEMs seeking dependable power for demanding EV applications.

Other noteworthy LBC Packs that align with performance and safety goals:

- 96 V 52 Ah LiFePO₄ Pack: Offers high energy density, low self-discharge, and long life fit for industrial and EV use cases

- 25.6 V 600 Ah LFP Pack (Metal Case): High-capacity solution tailored for heavy-duty and stationary EV deployments.

- 14.4 V 10 Ah NCM Pack: Compact NMC-powered pack for on-the-go or high-output applications, blending energy density with manageable form factor.

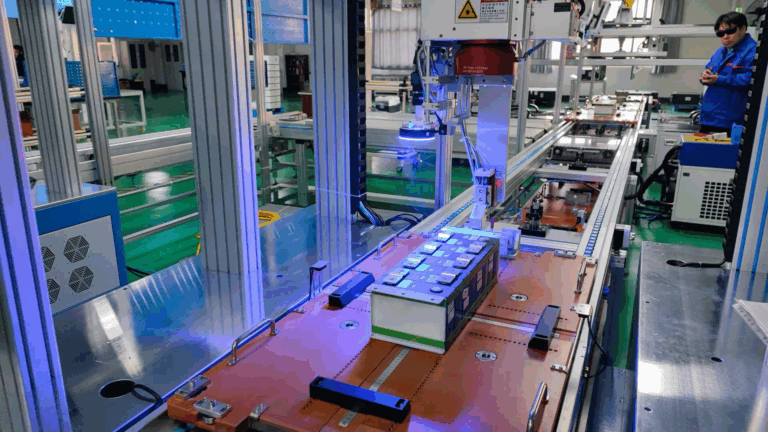

Why U.S. Automated Battery Manufacturing Matters for OEMs

Performance isn’t just about chemistry. It’s about how batteries are built. LBC’s automated U.S.-based manufacturing delivers:

- High-volume output with precision, with up to 2,000 high-quality packs per day in cleanroom environments.

- Advanced production features like robotic welding, real-time defect detection, in-line testing, and integrated BMS safety protocols.

- Customization and fast iteration are ideal for OEMs with unique voltage, packaging, or performance specs.

Lessons From Real-World EV Incidents

Events such as flooding-induced EV fires and thermal incidents in long-range packs highlight the necessity of systemic safety measures. These incidents reinforce the need for:

- Safe chemistries (like LFP)

- Strong system-level protections (BMS, cooling)

- Rigorous design, manufacturing, and emergency protocols

Sustainability and End-of-Life Considerations

OEMs are also facing growing regulatory pressure to address battery recycling and second-life use. LBC’s modular pack designs support refurbishment and repurposing, extending product lifecycle and helping OEMs meet sustainability targets.

The future of EV propulsion rests on aligning safety, performance, and OEM scalability. Lithium Battery Company achieves this through:

- Safety-focused LFP technology (e.g., the 400 V 84 kWh pack)

- More innovative controls, thermal systems, and manufacturing automation

- Custom, domestically produced battery solutions tailored to OEM demands

Lithium Battery Can Help You!

For manufacturing partners seeking reliable and scalable EV battery systems, LBC delivers performance, reliability, and safety built to empower the next wave of electric mobility. Contact us today!