Energy storage has moved from the background of industrial operations to the center of progress. In the past ten years, energy storage capabilities in the United States have skyrocketed, supporting innovation across industrial applications. Lithium batteries, with their superior energy density and long life cycle, are playing a critical role in this growth, transforming the way industries operate. Looking ahead, lithium batteries will continue to play a defining role in reshaping industrial applications worldwide. At the forefront of this transition is Lithium Battery Company (LBC), whose automated U.S.-based facility delivers the precision and scale industrial partners need to succeed.

Why Energy Storage Matters in Industrial Operations

Industrial sectors rely on consistent power to maintain productivity, minimize downtime, and control costs. Equipment failure, unstable grids, and outdated storage can quickly halt operations and cause significant financial loss. Rising energy prices and global sustainability pressures only add to the urgency for efficient, reliable energy systems.

Lithium batteries are a clear answer to this issue, meeting industry-standard backup runtimes of 8+ hours for critical nodes and supporting SCADA systems and NEBS-compliant infrastructure.. The result is greater efficiency, lower costs, and a more sustainable pathway for long-term growth across various industries.

Lithium Batteries vs. Traditional Energy Storage

Legacy energy storage systems, such as lead-acid batteries, have long been used in industrial settings. While familiar, they fall short in performance and scalability when compared to lithium batteries. Here are some of the key benefits of lithium batteries over traditional energy storage methods:

- Energy Density: Lithium batteries store more power in a smaller footprint, freeing valuable space in facilities.

- Cycle Life: They last significantly longer, with thousands of charge-discharge cycles compared to hundreds in lead-acid.

- Charging Speed: Faster charging times keep equipment running with less downtime.

- Maintenance: Virtually maintenance-free, unlike lead-acid systems that require regular upkeep.

For industries where efficiency directly impacts profitability, these differences translate into measurable advantages.

Industrial Applications Being Transformed

Transformation is occurring in the following areas.

Manufacturing

With innovations in automation and precision machinery, manufacturing facilities rely on lithium batteries for consistent voltage and reliable performance, ensuring smooth production lines and fewer interruptions. Backup energy systems further protect against costly downtime.

Warehousing and Logistics

Forklifts, automated guided vehicles (AGVs), and cold storage systems are moving toward lithium-based power. The longer cycle life and quick charging of lithium packs reduce downtime, keeping operations running around the clock.

Construction

Portable lithium battery packs are emerging as clean, quiet alternatives to diesel generators on job sites. They provide energy for tools, lighting, and temporary systems without emissions or excessive noise.

Telecommunications and Utilities

Network reliability depends on uninterrupted backup power. Lithium batteries offer stable, long-duration energy for telecom towers, substations, and emergency systems, ensuring critical infrastructure remains online.

Safety and Performance in Harsh Environments

Industrial environments often push equipment to the limit with extreme temperatures, vibration, and heavy load conditions. Lithium batteries are engineered to withstand these stresses while maintaining high safety standards.

Advanced Battery Management Systems (BMS) integrated into LBC packs protect against overcharging, deep discharge, and thermal runaway. This level of protection is especially critical in industries like telecommunications and defense, where energy stability and safety can have life-or-death consequences.

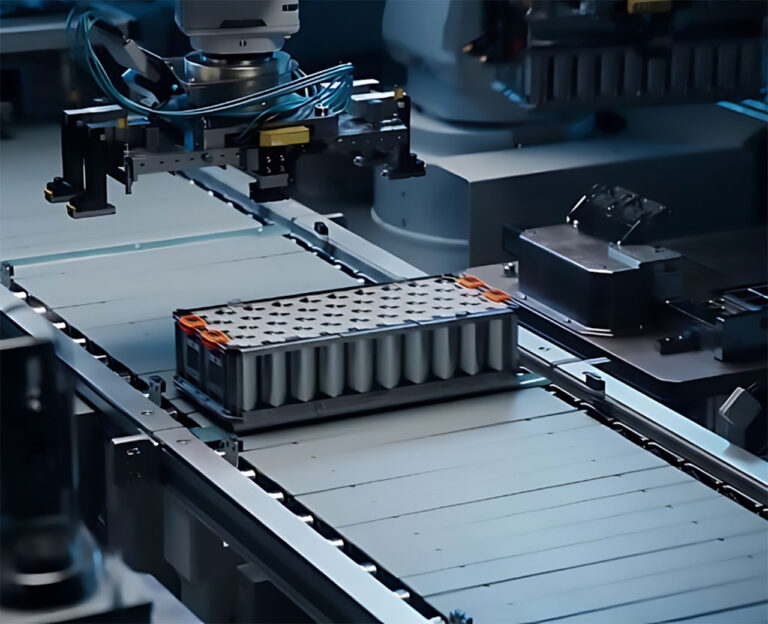

U.S.-Based Manufacturing for Industrial Partners

Global supply chain disruptions have highlighted the importance of reliable domestic production. By working with a U.S.-based manufacturer, industrial partners gain faster lead times, higher quality oversight, and greater customization flexibility.

At LBC’s 60,000-square-foot facility in Tampa, Florida, OEMs benefit from semi-automated assembly lines, cleanroom environments, and advanced testing capabilities. The facility supports cylindrical, prismatic, and sodium-ion pack assembly, giving industries options tailored to their specific applications. With its Foreign Trade Zone (FTZ) designation, LBC also streamlines international partnerships while keeping manufacturing anchored in the United States.

Lithium batteries are redefining what’s possible for industrial applications. By delivering superior performance, longer life, and enhanced safety, they are replacing outdated systems and enabling businesses to operate with greater efficiency and reliability. From manufacturing floors to construction sites, warehousing operations to telecom networks, lithium technology is setting the new standard for industrial energy storage.

Partner with Lithium Battery Company!

Lithium Battery Company is proud to lead this transformation. With automated U.S.-based manufacturing, rigorous quality control, and proven expertise across industries, LBC provides partners with energy storage systems that meet the demands of today while preparing them for the future. For industrial OEMs seeking reliable, scalable, and customized lithium battery solutions, Lithium Battery Company is the trusted partner to power tomorrow’s innovations.