Precision Prismatic Battery

Pack Assembly

At our advanced U.S.-based facility, we deliver high-volume, automated assembly of prismatic battery packs engineered for durability, consistency, and scale.

What Are Prismatic Battery Packs

and Why Do They Matter?

Prismatic cells offer a compact form factor with excellent space efficiency, ideal for applications in EV platforms, grid storage, aerospace systems, and industrial robotics. Their rigid housing makes them optimal for structured environments requiring high energy density and long cycle life.

From Raw Material to Final Pack

Automated, End-to-End

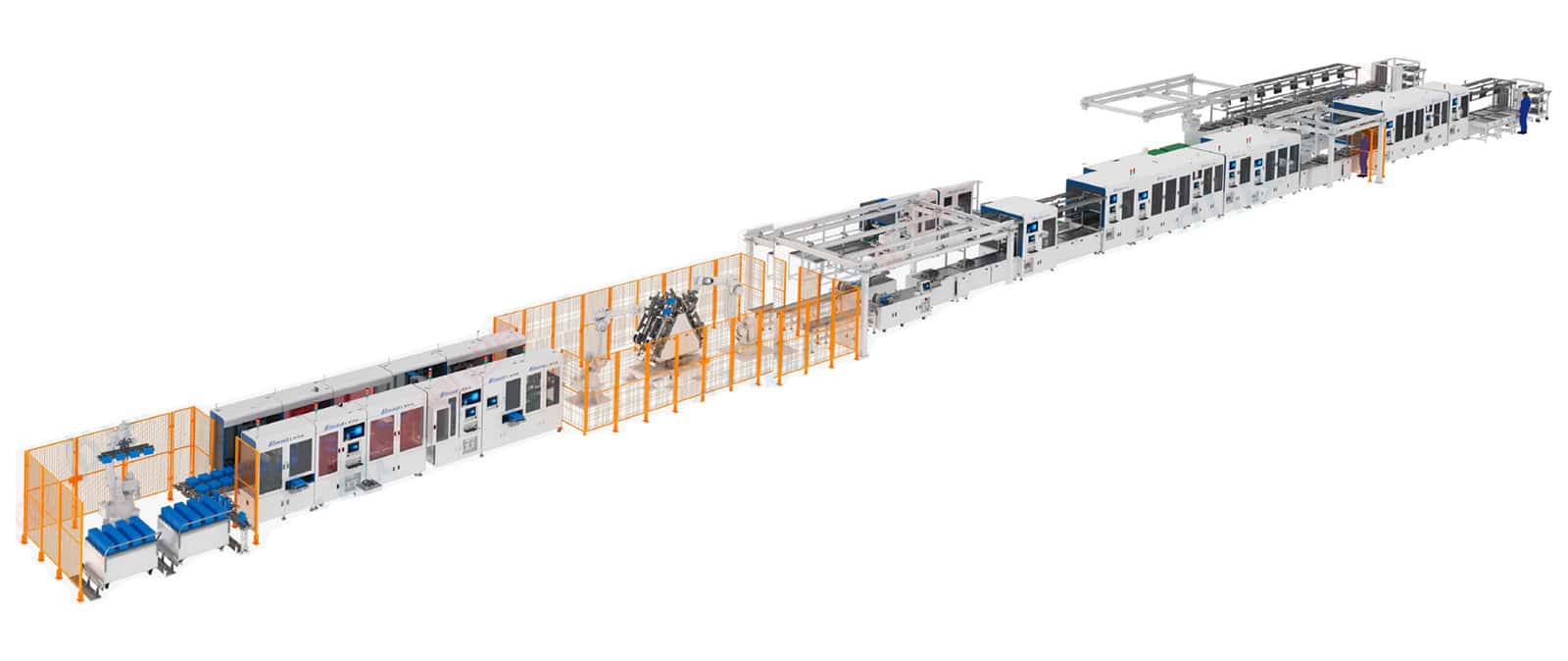

Our automation-first production line ensures seamless transitions across:

- Cell Loading and Staging

- Busbar Welding using precision-controlled six-axis robotics

- Structural Assembly & Sealing

- BMS Integration

- Final QC Testing including temperature, resistance, and visual inspection

Each step is built for speed, repeatability, and traceability.

A Facility Built for Excellence

- Fully automated lines designed for prismatic cell configurations

- Cleanroom-ready environments for sensitive pack builds

- Advanced robotics and in-line inspection systems

- Built-in scalability for high-throughput OEM production

Our systems are engineered to meet strict quality, safety, and compliance standards.

Testimonials

What Our Clients Say

Why Choose LBC for Prismatic Pack Assembly?

Faster time to market with high-speed automation

Superior build consistency and quality control

Seamless integration with your upstream / downstream supply chain

Made-in-USA production for tariff relief and stronger compliance

Get a Quote or

Schedule a Tour

Interested in learning more about our prismatic battery capabilities? Connect with our team for technical details, pricing, or to visit our Tampa facility.