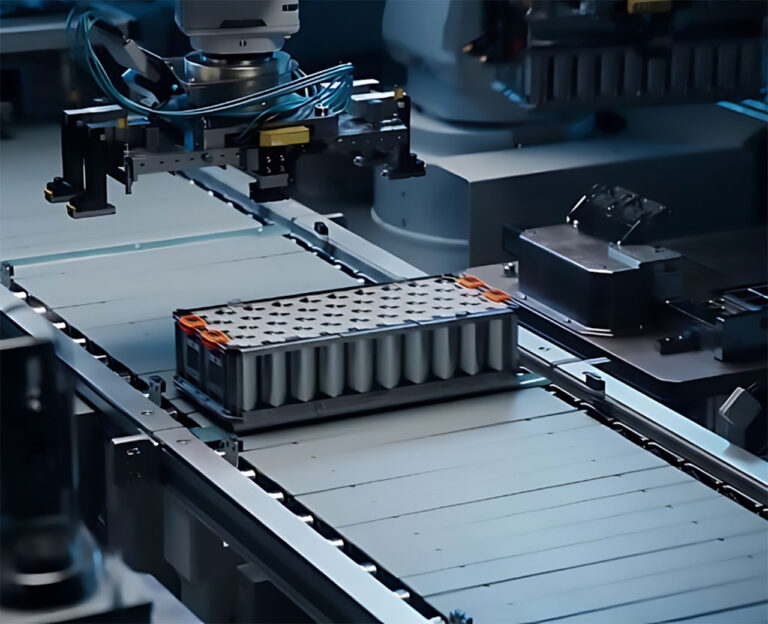

Powering the Grid with American-Made Energy Storage Solutions

Lithium Battery Company supports the future of energy storage with fully automated battery assembly lines built in the USA. From utility-scale systems to behind-the-meter applications, our advanced production facility delivers the quality, speed, and scalability energy providers demand.

A Facility Designed for Scalable Storage

Our Tampa, Florida facility is equipped with robotics, real-time monitoring systems, and cleanroom-ready assembly lines — enabling the high-volume production of battery packs for residential, commercial, and utility-grade energy storage systems (ESS). We help manufacturers streamline their storage solutions with precision and reliability.

Why Work With a U.S.-Based Partner?

Speed to Market: Shorter lead times and agile line changeovers

Built-in Quality: Automated inspection, AI-powered testing

Compliance Confidence: Supporting domestic energy goals and federal procurement standards

Economic Impact: Creating American jobs and reducing foreign dependency

Experienced Engineers. Proven Operators.

Our team brings decades of experience in lithium battery design, automation engineering, and large-scale production. Every project is backed by our in-house automation experts, ensuring seamless integration, top-tier quality assurance, and full technical support — from prototype to production ramp-up.

John Smith

Function

Lorem ipsum dolor sit amet, consectetur adipiscing elit.

John Smith

Function

Lorem ipsum dolor sit amet, consectetur adipiscing elit.

John Smith

Function

Lorem ipsum dolor sit amet, consectetur adipiscing elit.

John Smith

Function

Lorem ipsum dolor sit amet, consectetur adipiscing elit.

FAQs

We support a wide range of ESS applications, including home battery backups, commercial solar + storage systems, and utility-scale grid storage.

Yes. All of our lines are configured for full BMS integration, and we provide end-of-line testing for voltage, current, resistance, and safety protocols.

Absolutely. Our facility includes ISO-class clean areas for builds requiring environmental control.

Built-In Advantages for Energy Storage Clients

High-speed automation for large-format cylindrical and prismatic cells

Custom line design for high-voltage packs

Real-time defect detection and tracking

Seamless integration with upstream supply and downstream logistics

Support for thermal management and housing solutions

Let’s Power the Future — Together

Looking for a reliable battery partner for your energy storage system? Contact our team to schedule a call, request a quote, or tour our manufacturing facility.