Powering Defense Innovation: How Lithium Battery Company’s 48V 100Ah LiFePO4 Batteries Enabled the Success of General Dynamics’ MUTT Project

Military technology is evolving rapidly. American manufacturers must collaborate to maintain our nation’s defense capabilities. One partnership exemplifies this innovation perfectly.

Lithium Battery Company partnered with General Dynamics Land Systems on the groundbreaking MUTT project. Our Tampa facility provided the advanced 48V 100Ah LiFePO4 batteries. These batteries became the power source behind one of the most significant unmanned ground vehicle programs in recent military history.

This customer success story showcases American manufacturing excellence. Moreover, it demonstrates how innovative battery technology supports critical defense missions.

The Challenge: Meeting Military Power Demands

General Dynamics Land Systems faced a complex challenge. They needed to develop the MUTT system for the U.S. Army’s S-MET program. However, this required more than just engineering excellence.

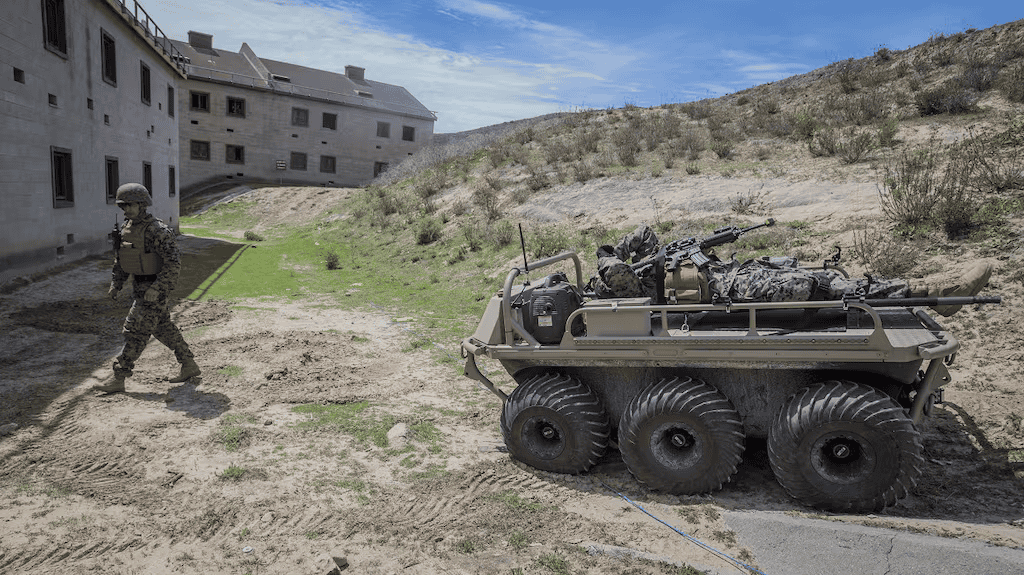

The project demanded a reliable, American-made power solution. Furthermore, it had to meet the rigorous demands of military operations [1]. The MUTT serves as a semi-autonomous robotic platform. Its primary purpose is reducing the physical burden on dismounted soldiers.

The battery system requirements were demanding. It needed consistent performance in harsh environments. Additionally, it had to maintain the reliability standards our armed forces expect.

Technical Specifications Required

The specifications were challenging. The system needed to power an 8×8 wheeled configuration. This configuration carries 1,200 pounds of payload across varied terrain. Export power capabilities reach up to 3kW. Operational ranges extend to 58 kilometers [2].

Traditional battery solutions couldn’t meet these requirements. Weight constraints presented additional challenges. Safety standards for military applications were non-negotiable.

Our Solution Approach

Lithium Battery Company’s expertise became invaluable. Our defense-grade lithium battery manufacturing capabilities were perfect for this challenge. Our Tampa-based facility specializes in high-stakes defense applications.

We developed specialized 48V 100Ah LiFePO4 battery packs. These became the heart of the MUTT system. Our unique position enabled us to deliver exactly what General Dynamics needed.

Understanding the MUTT: Revolutionary Military Technology

The Multi-Utility Tactical Transport represents a significant leap forward. Military robotics technology has never seen anything quite like it. The U.S. Army selected it in July 2020 for the S-MET program.

The contract was worth $162.4 million for 624 units. The MUTT has proven itself as “the most intuitive, capable and reliable UGV ever produced.” It’s also “the first of its kind to be selected for service alongside dismounted troops” [3].

Design Philosophy and Capabilities

The MUTT’s design centers on reducing soldier burden. Simultaneously, it enhances mission capabilities. Multiple configurations are available. These include 4×4, 6×6, and 8×8 variants.

The system operates in two modes. Semi-autonomous mode provides advanced functionality. Tele-operation mode offers direct control. Unique control methods include dismount following tether. Easy-to-use one-handed RC controllers are also available [4].

These features minimize soldiers’ physical loads. They also reduce cognitive loads during missions. This advantage is critical in modern warfare scenarios.

Technical Specifications

The 8×8 configuration became our collaboration focus. It measures 116 inches in length. Width reaches 70 inches. Gross vehicle weight totals 3,500 pounds.

Payload capacity is impressive. It carries 1,200 pounds while maintaining mobility. This works across diverse terrain. The capability makes it invaluable for military operations.

The system’s modular design allows various mission payloads. Future capabilities are planned. These include autonomous resupply and counter-unmanned aerial systems (C-UAS). Chemical, biological, radiological and nuclear (CBRN) defense is included. Intelligence, surveillance and reconnaissance (ISR) capabilities are planned. Electronic warfare (EW) and both direct and indirect fire capabilities will be added [5].

The Power Solution: 48V 100Ah LiFePO4 Technology

Our advanced 48V 100Ah LiFePO4 battery technology powers the MUTT’s success. This chemistry choice wasn’t arbitrary. LiFePO4 batteries offer considerable advantages for military applications.

High-power capabilities are a key benefit. Advantageous safety characteristics are another. Exceptional cycle life rounds out the advantages [6]. These attributes make them ideal for unmanned ground vehicles. Combat environments demand this level of performance.

Energy Storage and Performance

Our 48V 100Ah LiFePO4 battery packs deliver impressive capacity. Energy storage reaches 4.8 kWh. This provides the MUTT with necessary endurance for extended missions.

The 48-volt architecture was specifically chosen. It optimizes the balance between power delivery and system efficiency. The MUTT generates its required 3kW of export power. Operational ranges meet military specifications [7].

Safety Characteristics

LiFePO4 chemistry safety characteristics proved crucial. Unlike other lithium-ion chemistries, LiFePO4 batteries demonstrate exceptional thermal stability. They’re inherently resistant to thermal runaway.

This makes them significantly safer for military applications. Reliability under extreme conditions is paramount [8]. Their safety profile is excellent. They deliver consistent performance across wide temperature ranges. This made our LiFePO4 batteries the ideal choice for the MUTT program.

Our Manufacturing Role: From Concept to Deployment

Our collaboration with General Dynamics exemplifies comprehensive defense manufacturing. We took the project from initial research and development through full-scale deployment. This end-to-end capability operates from our Tampa facility.

This represents exactly the kind of reshoring manufacturing for national security that strengthens America’s defense industrial base.

Research and Development Phase

The project began in our R&D laboratories. Our engineering team worked closely with General Dynamics’ specifications. We developed a battery solution meeting the MUTT platform’s unique demands.

This wasn’t simply adapting existing battery technology. It required a ground-up approach. We designed a power system integrating seamlessly with the MUTT’s advanced control systems. Performance characteristics had to meet military operation requirements.

Manufacturing Excellence

Our large cylindrical battery assembly capabilities proved instrumental. Precision robotics and automated assembly systems at our Tampa facility enabled consistent manufacturing. Quality met defense application requirements.

Every battery pack underwent rigorous testing protocols. Laser-guided alignment verification was standard. Weld integrity testing was performed. Cell balancing and resistance testing occurred. Comprehensive final pack diagnostics happened before shipment [9].

Quality Standards

The manufacturing process reflects our commitment to defense-grade quality. Our facility operates under strict protocols. These ensure consistent weld quality and structural integrity.

Controlled environments protect sensitive components. Full traceability of materials and assemblies is maintained. Comprehensive data logging and validation support inspection and audits [10].

ITAR-aligned practices were essential. Documentation-ready reporting capabilities met stringent MUTT program requirements.

Scaling to Production

One significant challenge was scaling from prototype to production. The MUTT program required 624 units. Our manufacturing approach had to maintain R&D precision. Simultaneously, it needed throughput for military deployment schedules.

Our modular assembly lines provided the solution. Production capacity reaches up to 2,000 battery packs per day. This scalability met demanding timelines. Quality was never compromised [11].

Technical Innovation: Engineering Excellence

Developing our 48V 100Ah LiFePO4 battery packs required significant innovation. Multiple dimensions needed attention. Battery management system (BMS) integration alone was complex.

Seamless communication with the MUTT’s control systems was required. Safety monitoring and cell balancing were necessary. Reliable operation in field conditions was non-negotiable.

Battery Management System Development

Our engineering team developed a custom BMS solution. It monitors individual cell voltages in real-time. Temperature monitoring is continuous. Current flow tracking is constant. This ensures optimal performance throughout the battery pack’s operational life.

Sophisticated algorithms handle state-of-charge estimation. Thermal management is automated. Fault detection is immediate. All features are critical for maintaining operational readiness in military environments [12].

Mechanical Design Challenges

Battery pack mechanical design required careful consideration. The MUTT’s operational environment is demanding. Military ground vehicles face extreme vibration. Shock conditions are severe. Temperature variations are wide.

These factors can quickly degrade battery performance if not addressed. Our engineering team developed a robust enclosure system. It protects battery cells while maintaining thermal management. Optimal performance occurs across the MUTT’s operational temperature range.

Weight Optimization

Weight optimization represented another critical challenge. Every pound of battery weight impacts the MUTT’s payload capacity. Operational efficiency is also affected.

Our team achieved significant weight savings. Advanced cell selection was key. Packaging techniques were innovative. High-energy-density LiFePO4 cells were utilized. Configurations maximize energy storage while minimizing system weight [13].

Electrical Architecture

Battery pack electrical architecture was specifically optimized. The MUTT’s power requirements guided design decisions. The 48V nominal voltage provides ideal balance. Power delivery capability and system efficiency are optimized.

The 100Ah capacity ensures sufficient energy storage. Extended mission durations are supported. Battery packs deliver peak power outputs exceeding the MUTT’s 3kW requirement. Operational margin exists for demanding mission scenarios [14].

Manufacturing Process: Precision at Scale

Transitioning from prototype to full-scale production showcased our advanced capabilities. Our Tampa facility’s automated production lines were specifically configured. Defense-grade battery manufacturing has unique requirements.

Precision and quality control measures are necessary for military applications.

Incoming Inspection and Material Handling

Manufacturing begins with incoming inspection. All battery cells and components are tested. Advanced testing equipment verifies every component meets our standards.

Automated material handling systems ensure proper storage. Sensitive battery components require careful handling. Controlled environment conditions are maintained. This ensures consistent manufacturing results [15].

Cell Assembly Process

Cell assembly is the most critical manufacturing phase. Precision robotics systems perform laser-guided cell placement. Alignment is perfect. Optimal electrical connections are ensured. Mechanical stability is guaranteed.

Robotic welding systems utilize advanced monitoring technology. Weld quality is verified in real-time. AI-powered inspection systems detect anomalies. Long-term reliability is protected [16].

BMS Integration and Testing

Battery management system integration occurs under cleanroom conditions. Specialized equipment ensures proper calibration. All electronic components are tested thoroughly.

End-of-line testing procedures are comprehensive. Every battery pack undergoes performance verification. Capacity testing is performed. Power delivery is verified. Safety system validation occurs [17].

Quality Assurance

Quality assurance reflects our commitment to defense-grade standards. Statistical process control systems monitor key parameters in real-time. Automated alerts trigger for any deviations from tolerances.

Our quality management system maintains complete traceability. All materials and processes are tracked. Rapid identification and resolution of quality issues is possible [18].

Production Scalability

Our manufacturing approach scalability proved crucial. The MUTT program’s delivery schedules were demanding. Modular production line design allows rapid capacity expansion.

Cross-trained workforce ensures consistent quality. Production volume doesn’t affect standards. This flexibility enabled us to meet General Dynamics’ requirements. Quality standards expected for military applications were maintained [19].

Testing and Validation: Mission-Critical Reliability

Our MUTT battery pack testing program was rigorous. The critical nature of military applications demanded comprehensive protocols. Extreme conditions needed simulation.

Military systems require reliability levels far exceeding commercial applications.

Individual Cell Testing

Testing began with individual cell characterization. Sample cells underwent accelerated aging tests. Thermal cycling was performed. Vibration testing occurred. Abuse testing verified suitability for military applications.

Tests were conducted according to military standards. Data was necessary to optimize battery pack design. Maximum reliability and longevity were the goals [20].

System-Level Testing

Complete battery pack testing was comprehensive. Environmental testing covered the full operational temperature range. Mechanical testing simulated vibration and shock conditions. Ground vehicle applications were replicated.

Electrical testing verified performance under various load conditions. Environmental test chambers simulate temperature extremes. Range spans from -40°C to +85°C. Battery packs perform reliably across all operational conditions the MUTT might encounter [21].

Safety Testing

Safety testing was particularly critical. LiFePO4 batteries are inherently safer than other lithium-ion chemistries. However, comprehensive safety validation was still required for military applications.

Testing included overcharge scenarios. Overdischarge testing occurred. Short circuit testing was performed. Thermal abuse testing verified safe failure modes. Battery packs would fail safely even under extreme abuse conditions [22].

Field Testing

Field testing with General Dynamics provided final validation. Tests were conducted under realistic operational conditions. Battery packs delivered required performance and reliability.

Successful completion of field tests marked the transition. Development moved to full-scale production. Our design met all program requirements [23].

Deployment Success: Military Innovation in Action

MUTT systems powered by our 48V 100Ah LiFePO4 battery packs represent a significant milestone. Military robotics has reached new heights. The U.S. Army’s S-MET program selection validated both platform excellence and power solution reliability.

Deliveries began in 2021 [24].

Operational Feedback

Military units using MUTT systems provide consistent feedback. Power system reliability is consistently highlighted. Performance meets expectations. Extended operation without recharging is valuable.

Rapid recharge capability of our LiFePO4 technology proves invaluable. Military operations often have limited power availability [25].

International Success

The MUTT program’s international success further validates our battery technology. The British Army selected MUTT systems for their Army Warfighting Experiment. MUTT 8×8 variants were delivered in April 2020.

This demonstrates global appeal of American-made solutions [26]. International adoption reflects technical excellence. The MUTT platform is outstanding. American-made battery technology reliability is proven.

Platform Versatility

Our battery packs’ modular design enables platform adaptation. General Dynamics can configure the MUTT for various mission requirements. Different operational profiles are supported.

Short-duration high-power missions are possible. Extended-endurance surveillance operations are supported. This versatility maximizes the platform’s value [27].

Impact on American Defense Manufacturing

Our General Dynamics collaboration exemplifies broader impacts. Reshoring critical defense manufacturing capabilities to American soil is crucial. We developed and manufactured advanced battery systems in our Tampa facility.

This supported a critical military program. America’s defense industrial base was strengthened [28].

Economic Impact

The project created high-skilled manufacturing jobs in Tampa. Local economy benefits are significant. Capabilities built will support future defense programs.

Our investment in advanced manufacturing equipment represents long-term commitment. Workforce development extends far beyond the MUTT program [29].

Technology Transfer

Technical capabilities developed for the MUTT program have broad applications. Defense and commercial markets benefit. Advanced battery management systems are transferable. Manufacturing processes apply elsewhere. Quality control procedures enhance other applications.

Electric vehicles benefit from this technology. Energy storage systems utilize these advances [30].

Future Opportunities

MUTT program success positioned Lithium Battery Company favorably. We’re now a preferred supplier for other defense programs. Advanced battery technology requirements are our specialty.

Proven track record of delivering mission-critical power solutions opens doors. Schedule adherence is demonstrated. Specification compliance is proven. Additional opportunities to support America’s defense needs are available [31].

Future of Defense Power Systems

Our General Dynamics collaboration success provides a foundation. Future innovations in defense power systems are possible. Military systems are becoming increasingly electrified. Autonomous capabilities are expanding.

Demand for advanced battery technology will continue growing. Opportunities for continued innovation and collaboration are expanding [32].

Next-Generation Technologies

Our ongoing research and development focuses on next-generation battery technologies. Even more capable military systems will be enabled. Advanced cell chemistries are being developed. Battery management systems are improving. Packaging approaches are innovative.

Future platforms will achieve greater performance. Longer operational ranges are possible. Enhanced mission capabilities will be standard [33].

Lessons Learned

MUTT program lessons inform our future defense collaborations. Early engagement in the design process is important. Comprehensive testing and validation provide value. Manufacturing scalability is critical.

These factors contribute to our ability to support future defense programs effectively [34].

Continuous Improvement

Our commitment to continuous improvement ensures leadership in defense battery technology. Ongoing investments in research and development continue. Manufacturing capabilities are expanding. Workforce development is ongoing.

We’re positioned to support America’s defense establishment’s evolving needs for years to come [35].

Conclusion: Partnership Powering American Defense

The successful collaboration between Lithium Battery Company and General Dynamics represents more than a customer relationship. It exemplifies innovation and excellence that American manufacturing can achieve. Our focus on supporting our nation’s defense needs drives results.

Our 48V 100Ah LiFePO4 battery packs became integral to a revolutionary military platform. American forces around the world have enhanced capabilities.

Comprehensive Capabilities Demonstrated

This project showcases our Tampa facility’s comprehensive capabilities. Initial research and development through full-scale production and deployment occurred here. Complex defense requirements were translated into reliable, high-performance battery solutions.

American manufacturing expertise value in supporting critical defense programs is demonstrated.

Commitment to the Future

Lithium Battery Company remains committed to supporting America’s defense needs. Continued innovation in battery technology continues. Manufacturing excellence is our standard.

Our General Dynamics partnership established a foundation. Future collaborations will continue strengthening America’s defense capabilities. Domestic manufacturing growth is supported.

Setting New Standards

The MUTT project success story demonstrates American company collaboration results. Defense innovation can exceed expectations. New standards for excellence are set.

We’re proud to have played a crucial role. This revolutionary military platform is powered by our technology. We look forward to continuing our support. America’s defense needs will be met through advanced battery technology and manufacturing excellence.

Your Defense Battery Solution

Organizations seeking reliable, American-made battery solutions for defense applications should consider Lithium Battery Company. We offer proven expertise. Manufacturing capabilities are demonstrated. Commitment to excellence is shown through our General Dynamics collaboration.

Contact us today to learn how our defense-grade battery manufacturing capabilities can support your critical mission requirements.

References

- General Dynamics Land Systems. “S-MET – Multi-Utility Tactical Transport (MUTT).”

- Army Technology. “Multi-Utility Tactical Transport (MUTT) UGV, United States of America.”

- General Dynamics Land Systems. “S-MET – Multi-Utility Tactical Transport (MUTT).”

- Army Technology. “Multi-Utility Tactical Transport (MUTT) UGV, United States of America.”

- General Dynamics Land Systems. “S-MET – Multi-Utility Tactical Transport (MUTT).”

- Department of Defense. “Department of Defense Awards $12.9 Million to Increase Production of Active Materials for Lithium Iron Phosphate Batteries.”

- Army Technology. “Multi-Utility Tactical Transport (MUTT) UGV, United States of America.”

- Luso Electronics. “Lithium Iron Phosphate Battery UPS Systems for Military Applications.”

- Lithium Battery Company. “Large Cylindrical Battery Assembly – Automated Precision.”

- Lithium Battery Company. “Defense-Grade Lithium Batteries – MIL-SPEC Compliant.”

- Lithium Battery Company. “American Lithium Battery Manufacturing | Custom & Scalable.”

- RICHYE. “Lifepo4 Batteries For Military.”

- Dakota Lithium. “48V 100Ah Deep Cycle LiFePO4 Battery Set.”

- Army Technology. “Multi-Utility Tactical Transport (MUTT) UGV, United States of America.”

- Lithium Battery Company. “Large Cylindrical Battery Assembly – Automated Precision.”

- Lithium Battery Company. “Large Cylindrical Battery Assembly – Automated Precision.”

- Lithium Battery Company. “Defense-Grade Lithium Batteries – MIL-SPEC Compliant.”

- Lithium Battery Company. “Defense-Grade Lithium Batteries – MIL-SPEC Compliant.”

- Lithium Battery Company. “American Lithium Battery Manufacturing | Custom & Scalable.”

- Federal Railroad Administration. “Safety Testing of Lithium-Ion Batteries for Military Applications.”

- RICHYE. “Lifepo4 Batteries For Military.”

- Federal Railroad Administration. “Safety Testing of Lithium-Ion Batteries for Military Applications.”

- Army Technology. “Multi-Utility Tactical Transport (MUTT) UGV, United States of America.”

- General Dynamics Land Systems. “General Dynamics Land Systems Delivers S-MET, the U.S. Army’s Small Multipurpose Equipment Transport.”

- Army Technology. “Multi-Utility Tactical Transport (MUTT) UGV, United States of America.”

- Army Technology. “Multi-Utility Tactical Transport (MUTT) UGV, United States of America.”

- General Dynamics Land Systems. “S-MET – Multi-Utility Tactical Transport (MUTT).”

- Lithium Battery Company. “Defense-Grade Lithium Batteries – MIL-SPEC Compliant.”

- Lithium Battery Company. “American Lithium Battery Manufacturing | Custom & Scalable.”

- Lithium Battery Company. “American Lithium Battery Manufacturing | Custom & Scalable.”

- Lithium Battery Company. “Defense-Grade Lithium Batteries – MIL-SPEC Compliant.”

- Department of Defense. “DoD Lithium Battery Strategy 2023-2030.”

- Department of Defense. “Department of Defense Awards $12.9 Million to Increase Production of Active Materials for Lithium Iron Phosphate Batteries.”

- Lithium Battery Company. “Defense-Grade Lithium Batteries – MIL-SPEC Compliant.”

- Lithium Battery Company. “American Lithium Battery Manufacturing | Custom & Scalable.”