Announcing Our New State-of-the-Art Lithium Battery Factory in Tampa, FL

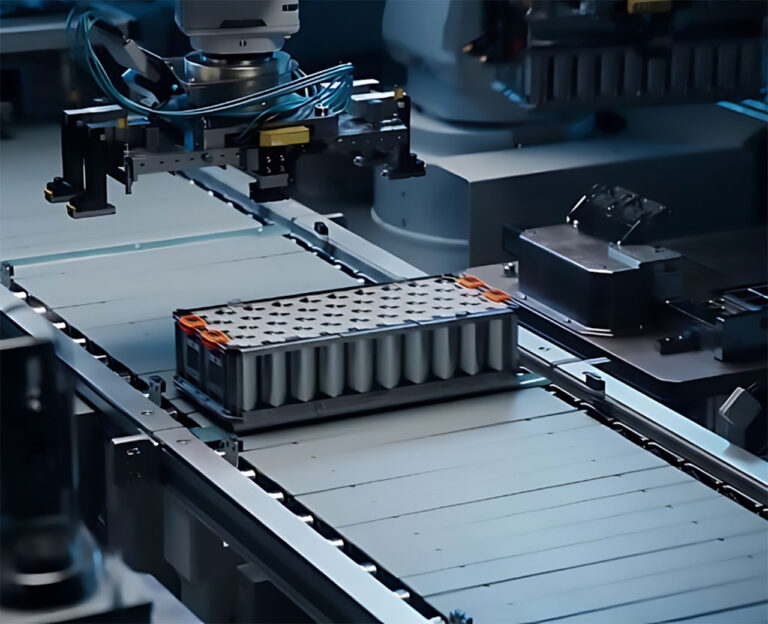

Lithium Battery Company is proud to announce the launch of our advanced, fully automated battery manufacturing facility in Tampa, Florida—a major milestone in our mission to lead the world in energy storage innovation and to reshore American manufacturing jobs. Explore our fully automated battery pack assembly lines below.

A New Era for American Battery Manufacturing

Our new 83,000-square-foot facility, located in South Tampa, represents a $4 million investment and the largest expansion in our company’s history. This site is more than just a factory; it’s a hub for high-tech job creation and a showcase for the future of clean energy manufacturing in the United States. Over the next three years, we plan to add 150 new high-tech jobs, supporting both the local economy and our nation’s energy independence.

Cutting-Edge Automated Assembly Lines

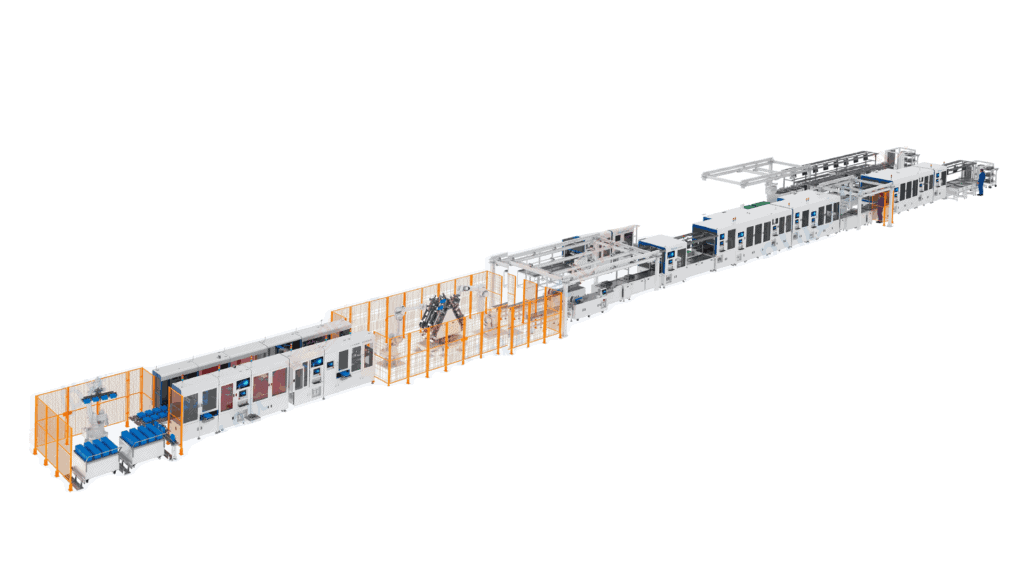

At the heart of our South Tampa facility are five specialized, automated assembly lines designed to meet the diverse needs of modern energy storage—ranging from small electronics to utility-scale systems. Our capabilities include:

Fully Automated Large Prismatic Battery Assembly Line: Precision assembly for high-capacity prismatic cells, ideal for commercial energy storage and electric vehicles. This line features advanced automation for cell sorting, welding, and quality control, ensuring consistency and safety at scale.

Supported Cells:

-

Prismatic cells, typically 50Ah to 320Ah

Popular Applications:

-

Electric vehicles (cars, buses, e-bikes)

-

Energy storage systems (solar, wind, grid-scale)

-

Containerized Battery Energy Storage Systems (BESS) for industrial, utility, and grid applications, often in 20-foot or 40-foot containers using high-capacity prismatic cells

-

Robotics and industrial equipment

-

Marine and recreational vehicles

-

Portable power stations and emergency backup systems

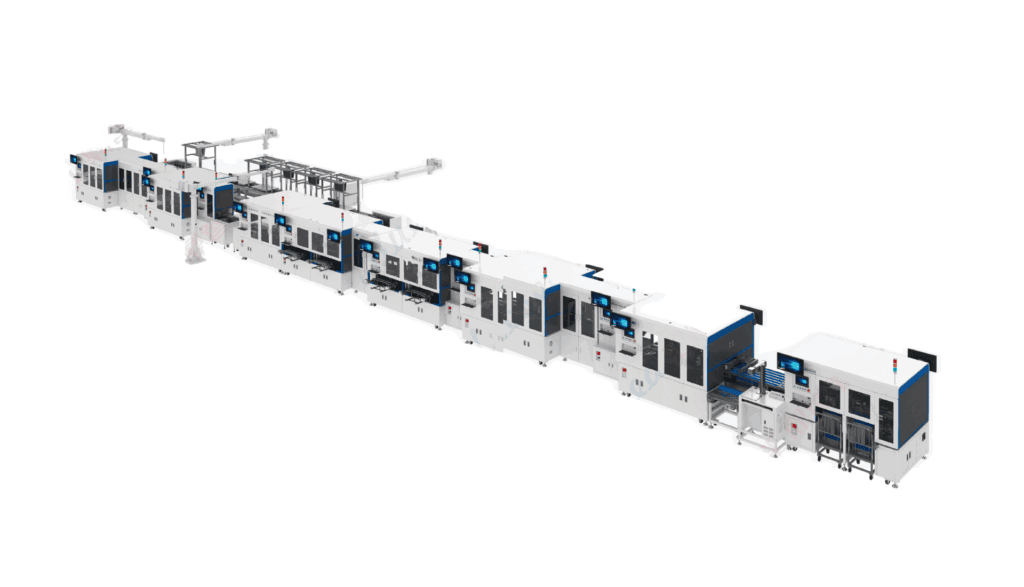

Fully Automated Large Cylindrical Battery Assembly Line: High-speed production for large cylindrical cells, supporting applications from grid storage to defense. Automation covers the entire process from electrode preparation to final inspection, delivering reliability and efficiency.

Supported Cells:

-

32130

-

32125

-

32140

-

22140

-

40130

-

4680

Popular Applications:

-

Electric vehicles (cars, buses, commercial vehicles)

-

Energy storage systems (residential, commercial, grid-scale)

-

Industrial and commercial backup power (UPS, data centers)

-

Robotics and automated guided vehicles (AGVs)

-

Marine and recreational vehicles

-

Heavy-duty equipment and high-performance applications

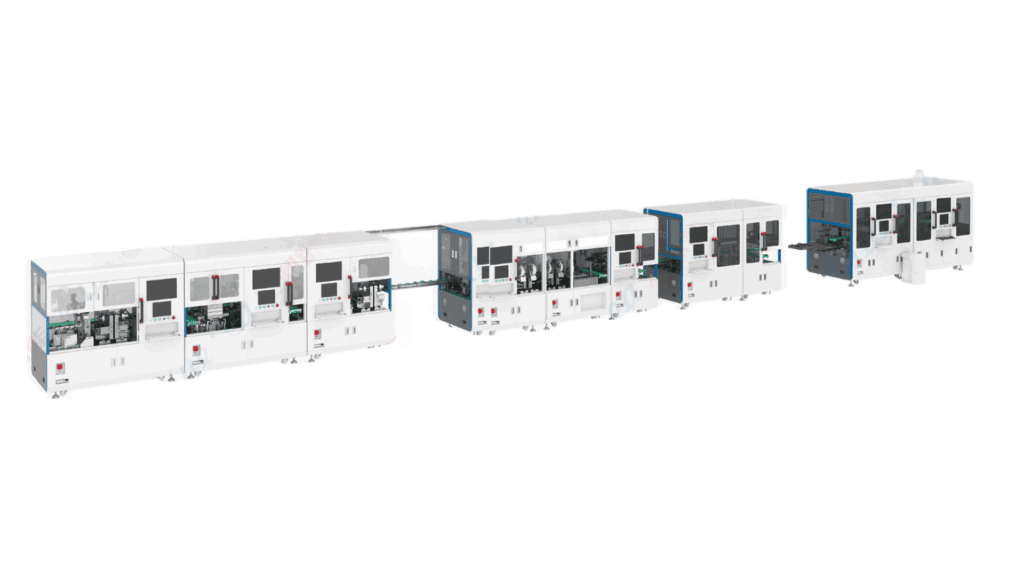

Fully Automated Small Cylindrical Battery Assembly Line: Tailored for compact, high-performance cells used in consumer electronics and portable devices. This line maximizes throughput while maintaining stringent quality standards.

Supported Cells:

-

18650

-

21700

-

26650

-

32700

Popular Applications:

-

Portable electronics (laptops, cameras, power banks)

-

Power tools

-

Medical devices

-

E-bikes, e-scooters, and small EVs

-

Solar energy storage and backup power systems

Our facility also features a clean room environment for sensitive components, advanced testing and validation labs, climate-controlled storage, ESD-protected work areas, and comprehensive quality control systems.

Unmatched Manufacturing Capabilities

Power Range: From small battery packs to 1 MW systems

Voltage Range: 3.7V to 1500V

Capacity Range: 1Ah to 9 MWh

Custom BMS Integration: Tailored battery management systems for every application

Our advanced lines are designed to support a wide array of markets, including defense, AI data centers, renewable energy, and electric vehicles. We are proud to serve both government and commercial clients, with a proven track record of reliability and innovation.

Reshoring American Jobs and Manufacturing

Our expansion is about more than technology—it’s about bringing manufacturing back to the United States. By relocating production from overseas and investing in American talent, we are helping to secure the nation’s energy future, reduce supply chain risk, and create high-quality jobs in Tampa Bay. This move is supported by government incentives and reflects a growing national commitment to domestic battery manufacturing, as seen in recent federal initiatives and investments.

“When we started looking at the whole equation, we estimated around 20 percent cost savings by not having the battery packs manufactured overseas,” said Nathan Staron, CEO. “There is a lot of energy to make this happen here, so we are very excited about it… It does feel good to bring back manufacturing jobs, but the next challenge is going to be able to find the people to be able to run the equipment and teach them and train them.”

A Commitment to Sustainability and Community

Our mission is to accelerate the world’s transition to sustainable energy through innovative battery solutions, while upholding the highest standards of quality, safety, and environmental responsibility. We are excited to collaborate with local partners, universities, and the Tampa Bay Economic Development Council to foster talent and drive innovation in the region.

Join Us in Powering America’s Future

Lithium Battery Company’s new South Tampa facility is more than an investment in technology—it’s an investment in people, community, and the future of American manufacturing. We invite you to follow our journey as we continue to push the boundaries of energy storage and help make “Made in America” the standard in battery technology once again.

For more information and to explore our fully automated battery pack assembly lines, contact us at Lithium Battery Company or visit our South Tampa facility.

Together, we’re building the batteries—and the jobs—that will power America’s tomorrow.