Automated Large Cylindrical Battery Assembly at Scale

Harness the power of precision robotics and U.S.-based automation to build high-capacity cylindrical battery packs for energy storage, EVs, and industrial systems.

Efficiency Engineered Into Every Pack

Our automated systems are optimized for the high-volume production of large cylindrical battery cells. From alignment to welding, every step is designed for accuracy, speed, and consistency.

Built-In Quality at Every Stage

We apply strict quality assurance protocols to ensure safe, reliable battery packs:

- Laser-guided alignment

- Weld integrity verification

- Cell balancing and resistance testing

- Final pack diagnostics before shipment

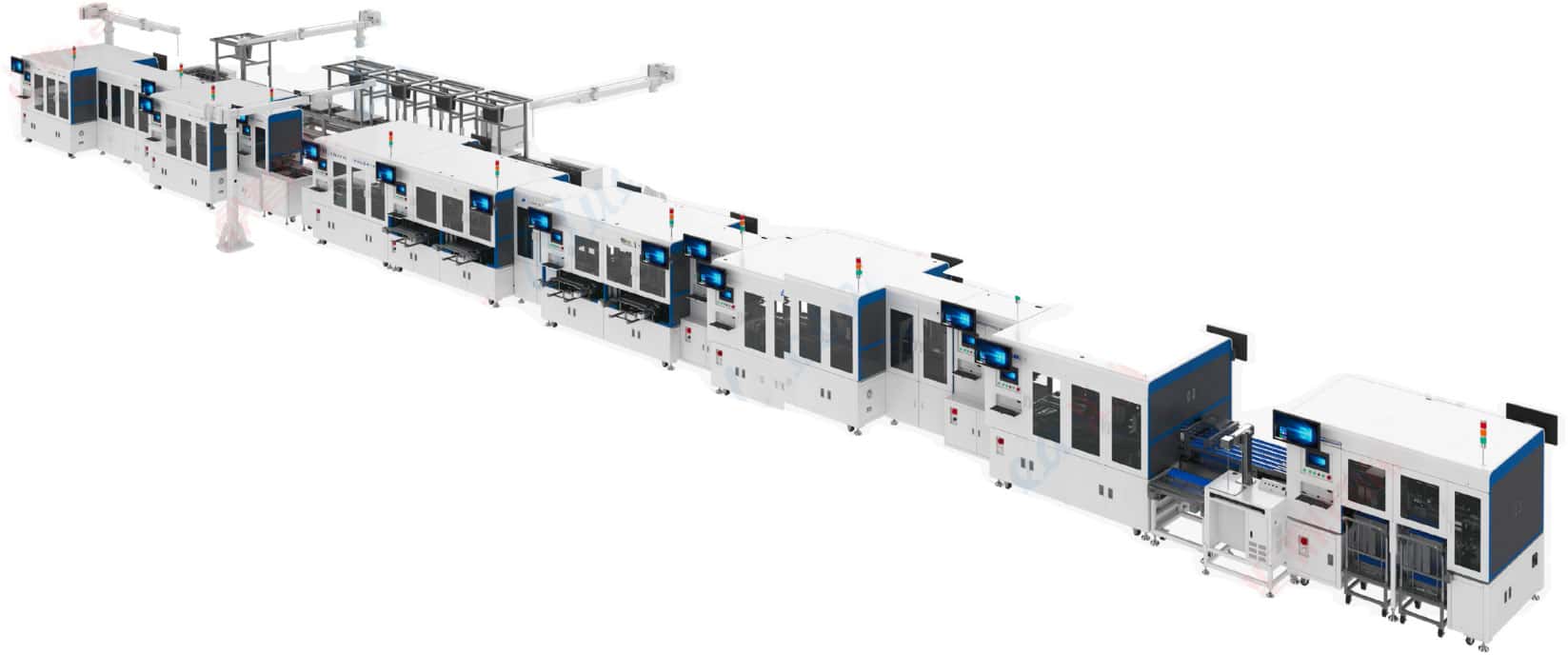

Scalability to Match Your Growth

Whether you're launching a new product or expanding an existing platform, our modular assembly lines adapt quickly to meet your production goals — without sacrificing precision or timeline.

Our Process:

End-to-End Automation

1

Material Staging

2

Cell Orientation and Placement

3

Robotic Welding and Busbar Connection

4

BMS Integration

5

Sealing, Labeling, and Final QC

Our engineers optimize every workflow for repeatability, uptime, and throughput.

Proven Performance Metrics

Up to

packs/day capacity per line

defect rate with in-line quality checks

reduction in manual labor requirements

ISO-compliant protocols in progress

Testimonials

What Our Clients Say

Let’s Build Something Powerful Together

Ready to scale your cylindrical battery production? Reach out to schedule a tour or request a custom quote tailored to your application.