Reshore Your EV Battery Manufacturing with

Our State-of-the-Art

Facility

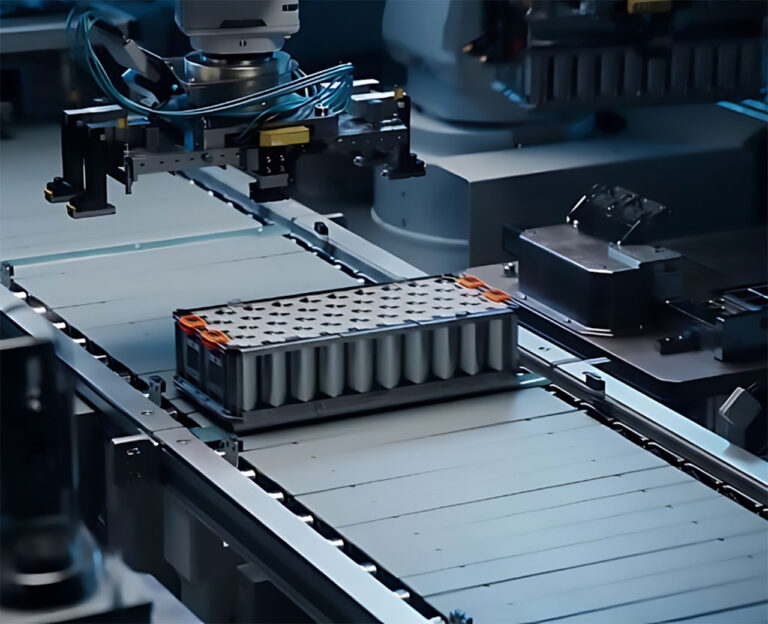

Lithium Battery Company offers fully automated, U.S.-based EV battery pack assembly solutions. From prototyping to production scale, we help OEMs accelerate timelines, improve reliability, and strengthen their supply chains.

Advanced Automation

Unmatched Precision

Our facility is equipped with six-axis welding, real-time monitoring, and smart robotics — enabling ultra-consistent, high-throughput production of prismatic and cylindrical battery packs. Every step is optimized for traceability, repeatability, and industry compliance.

Reshoring Manufacturing

Reclaiming Control

By bringing EV battery assembly back to the U.S., we help OEMs reduce lead times, cut logistics costs, and improve supply chain resilience. Our domestic facility supports American jobs while enabling faster response to market shifts and customer demand.

Why Leading EV Companies

Choose LBC ?

Advanced Automation Technology

High-speed, high-precision battery lines

High-Quality Production Standard

Cleanroom capability, BMS integration, end-of-line testing

Economic & Supply Chain Benefits

Reduced overseas reliance, faster delivery, Made-in-USA compliance

Testimonials

What Our Clients Say

Case Studies

We’ve Helped EV Clients ...

... across the U.S. ramp up from concept to production-ready in record time. Our flexible, automated lines enable fast changeovers, clean assembly environments, and defect rates under 1%.

EV Client Boosts Output by 3X with Automated Prismatic Lines

Micromobility Brand Reduces Assembly Time by 40%

Ready to

Reshore Your

EV Battery Manufacturing?

Contact us to schedule a facility tour, discuss technical requirements, or request a custom quote.